How Is Protein Powder Made

How Is Protein Powder Made

Protein powder has become a popular nutritional supplement for athletes, fitness enthusiasts, and those seeking to increase their protein intake. But have you ever wondered how this powdered form of protein is made? In this article, we will delve into the fascinating process behind the production of protein powder, from understanding the basics to quality control, packaging, and even the environmental impact.

Understanding the Basics of Protein Powder

Before diving into the production process, it is important to grasp the role of protein in the body. Protein plays a crucial role in muscle growth, repair, and maintenance. It is also essential for the synthesis of enzymes, hormones, and other molecules necessary for proper bodily function. Protein powders are concentrated sources of protein derived from various sources, such as whey, soy, or pea.

The Role of Protein in the Body

Protein is made up of amino acids, known as the building blocks of life. When we consume protein, our bodies break it down into these smaller units, which are then absorbed and used to repair and build tissues. The amino acids also serve as a fuel source when carbohydrates are not readily available.

Protein is particularly important for athletes and those engaged in regular physical activity. It helps to support muscle growth, aids in post-workout recovery, and can enhance overall performance.

In addition to its role in muscle growth and repair, protein also plays a vital role in various other bodily functions. It is involved in the production of enzymes, which are essential for digestion and metabolism. Protein also helps in the production of hormones, which regulate various processes in the body, including growth, reproduction, and mood. Furthermore, protein is a key component of the immune system, helping to fight off infections and diseases.

Another important aspect of protein is its ability to promote satiety. When we consume protein-rich foods or supplements, they help us feel full and satisfied for longer periods. This can be beneficial for individuals looking to manage their weight or control their appetite.

Different Types of Protein Powders

There are several types of protein powders available on the market, each with its own unique properties and benefits. Some of the most common types include:

- Whey protein: This is the most popular protein powder and is derived from milk. It is quickly absorbed and rich in essential amino acids. Whey protein is often favored by athletes and bodybuilders due to its rapid digestion and high bioavailability.

- Soy protein: Made from soybeans, this protein powder is suitable for individuals with lactose intolerance or those following a vegetarian or vegan diet. Soy protein is a complete protein, meaning it contains all the essential amino acids required by the body.

- Pea protein: Derived from yellow split peas, this plant-based protein powder is an excellent option for those with allergies or sensitivities to dairy or soy. Pea protein is also rich in essential amino acids and is easily digestible.

Aside from these popular options, there are also protein powders available that are made from hemp, rice, and even insect sources. Each type of protein powder offers its own unique nutritional profile and can cater to different dietary preferences and restrictions.

It is important to note that the effectiveness and suitability of a protein powder may vary depending on individual needs and goals. Consulting with a healthcare professional or registered dietitian can help determine the best protein powder for specific requirements.

The Production Process of Protein Powder

Now that we have a basic understanding of protein powder, let's explore the production process in more detail.

Protein powder has become a popular dietary supplement among athletes, fitness enthusiasts, and individuals looking to increase their protein intake. It is a convenient and versatile way to add protein to one's diet, and its production involves several steps to ensure quality and purity.

Sourcing the Raw Materials

The first step in protein powder manufacturing is sourcing the raw materials. For whey protein, milk is collected from dairy farms and undergoes a filtration process to separate the whey protein from the liquid portion. This filtration process helps remove any impurities and unwanted components, leaving behind a protein-rich liquid.

For plant-based proteins, such as soy or pea, the respective crops are harvested and processed to extract the protein-rich portion. These raw materials are carefully selected and tested to ensure they meet the required quality standards.

Once the raw materials are collected, they are transported to the production facility for further processing. This transportation process involves careful handling and storage to maintain the integrity of the raw materials.

The Extraction of Protein

Once the raw materials reach the facility, the protein extraction process begins. In the case of whey protein, the liquid whey undergoes further processing through filtration and purification steps to remove any impurities, fats, and lactose. This ensures that the final product is pure and free from unwanted substances.

For plant-based proteins, the extracted materials undergo a similar purification process to obtain a concentrated protein powder. This process involves separating the protein from other components, such as carbohydrates and fibers, to create a protein-rich powder.

During the extraction process, quality control measures are implemented to monitor the protein content and ensure consistency in the final product. This involves regular testing and analysis to meet the desired protein concentration.

The Process of Drying and Powdering

After the extraction process, the purified protein is dried to remove any remaining moisture. This is typically done through a combination of heat and air drying methods to preserve the quality and nutritional content of the protein.

Drying is a critical step as it helps extend the shelf life of the protein powder and prevents the growth of bacteria or mold. The drying process is carefully monitored to ensure that the protein is not exposed to excessive heat, which could denature the protein and reduce its effectiveness.

Once the protein is dry, it is then ground into a fine powder. This powder can then be flavored, sweetened, or mixed with other ingredients to enhance taste and improve solubility. The addition of flavors and sweeteners allows for a variety of options to cater to different preferences.

Before packaging, the protein powder undergoes rigorous quality control checks to ensure that it meets the specified standards. This includes testing for protein content, purity, and absence of contaminants.

The production process of protein powder requires careful attention to detail and adherence to strict quality control measures. By following these steps, manufacturers can produce high-quality protein powder that meets the needs and expectations of consumers.

Quality Control in Protein Powder Manufacturing

Ensuring the quality and safety of protein powder is of paramount importance. Manufacturers implement strict quality control measures throughout the production process to maintain the highest standards.

When it comes to protein powder manufacturing, quality control is a multifaceted process that involves various steps and checks. Let's delve deeper into some of the key aspects of quality control in this industry.

Testing for Purity and Safety

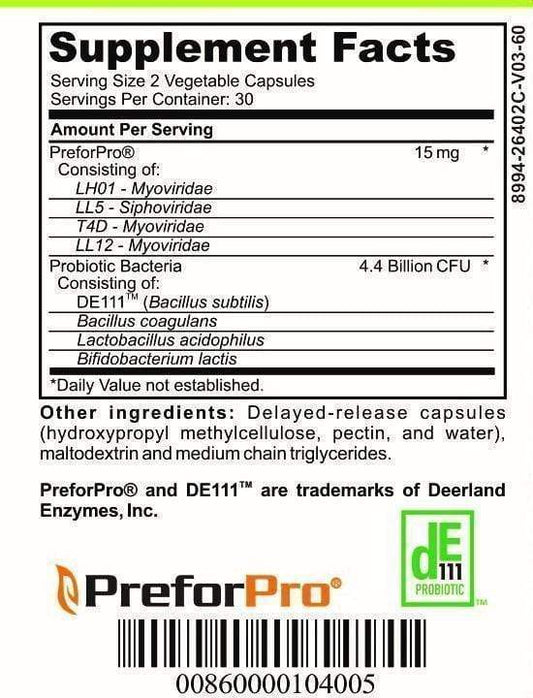

Protein powders undergo rigorous testing to ensure they are free from contaminants and meet regulatory standards. This includes testing for heavy metals, microbial contaminants, and allergenic substances.

Heavy metal testing is crucial as these substances can accumulate in the body over time and cause adverse health effects. By conducting thorough tests, manufacturers can ensure that their protein powders are within safe limits for heavy metal content.

Microbial contaminants, such as bacteria and molds, can pose serious health risks if present in protein powders. To prevent contamination, manufacturers implement strict sanitation protocols and regularly test their products for microbial growth.

Allergenic substances, such as gluten or lactose, are also carefully monitored in protein powder manufacturing. Manufacturers take precautions to avoid cross-contamination during production and conduct allergen testing to guarantee that their products are safe for individuals with specific dietary restrictions or allergies.

Additionally, reputable manufacturers regularly conduct third-party testing to further validate the quality and safety of their products. This independent verification provides an extra layer of assurance for consumers, ensuring that the protein powders they purchase meet the highest standards of quality and safety.

Ensuring Nutritional Value

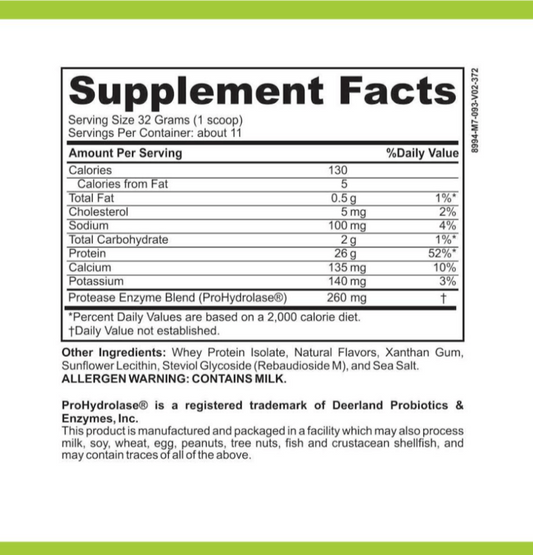

During the production process, manufacturers aim to preserve the nutritional value of the protein powder. Careful temperature control and minimal processing help retain the amino acid profile and bioavailability of the protein.

Temperature control is crucial to prevent denaturation of the protein. By carefully monitoring and adjusting the temperature during processing, manufacturers can maintain the integrity of the protein structure, ensuring that it retains its nutritional value and functional properties.

Minimal processing is another key aspect of quality control in protein powder manufacturing. Excessive processing can lead to the loss of essential nutrients and bioactive compounds. Manufacturers strive to strike a balance between ensuring product safety and preserving the nutritional integrity of the protein powder.

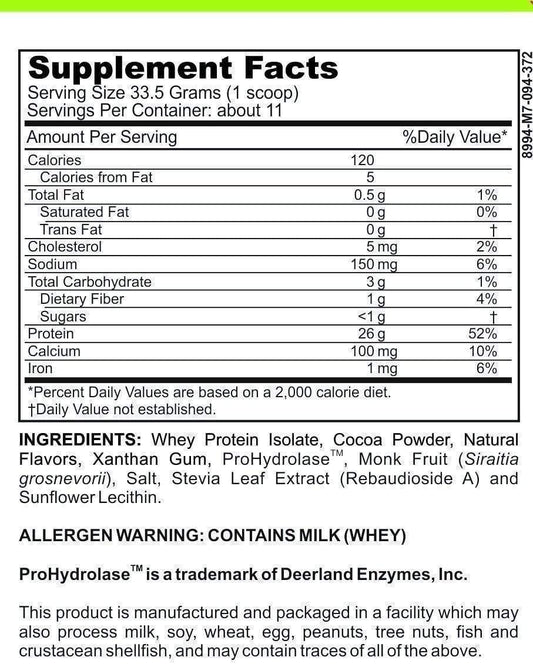

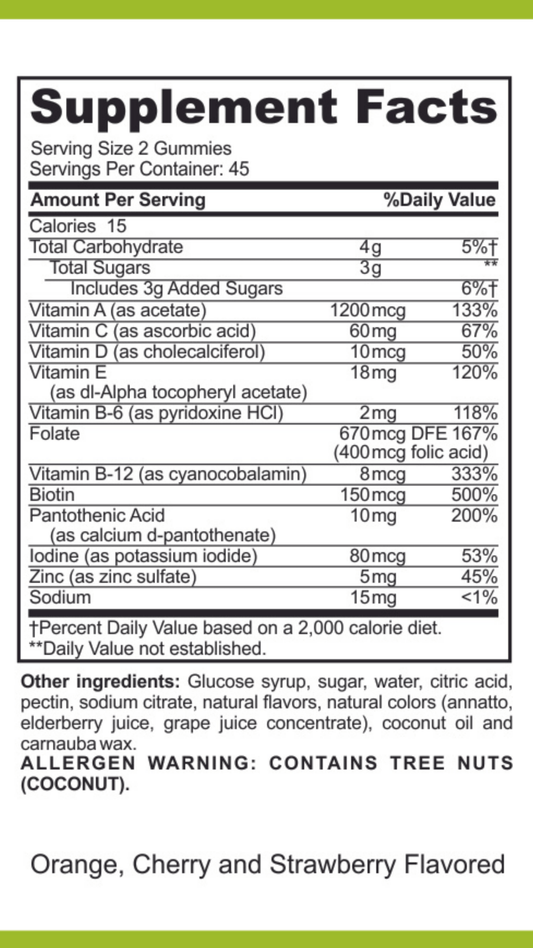

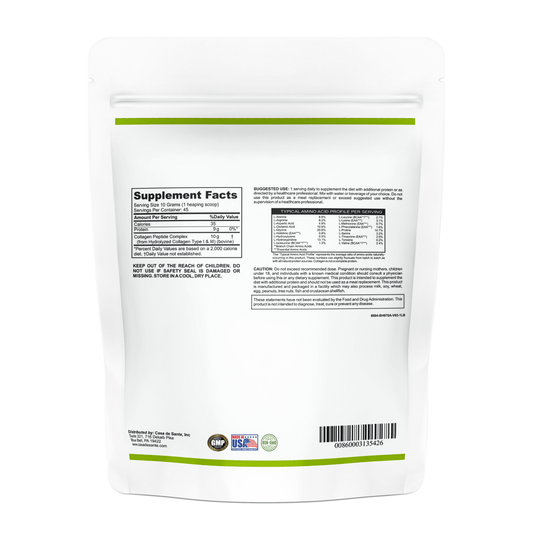

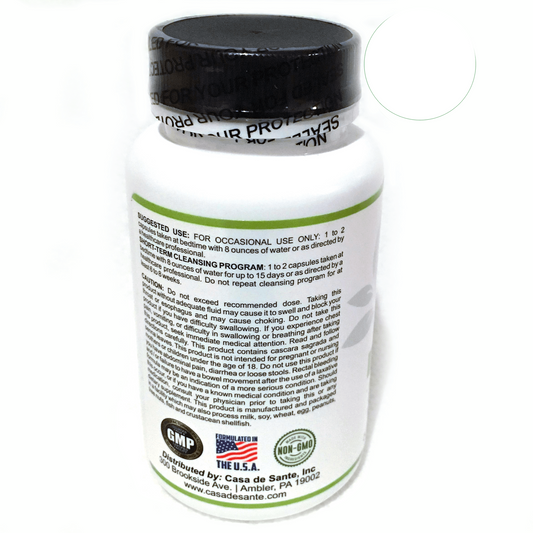

Labels on protein powder packaging provide nutritional information, including the total protein content, essential amino acids, and other key nutritional facts. Consumers can use this information to make informed choices based on their dietary needs and goals.

Moreover, some manufacturers go the extra mile by conducting additional tests to verify the accuracy of the nutritional information on their labels. This commitment to transparency and accuracy ensures that consumers have access to reliable information when selecting protein powders.

In conclusion, quality control in protein powder manufacturing is a comprehensive process that involves rigorous testing for purity and safety, as well as measures to preserve the nutritional value of the product. By adhering to these strict quality control measures, manufacturers can provide consumers with protein powders that are not only safe but also meet their nutritional needs.

Packaging and Distribution of Protein Powder

After the production process is complete, protein powder is packaged in various forms, such as tubs, pouches, or single-serving packets. Packaging plays a crucial role in preserving the freshness and quality of the product.

The Importance of Proper Packaging

Protein powder is highly susceptible to moisture, heat, and oxygen, which can degrade its quality and nutritional value. Therefore, manufacturers use specialized packaging materials that provide a barrier against these elements.

Sealed containers with airtight lids and desiccant packets are commonly used to maintain the freshness of the powder, ensuring that it remains suitable for consumption over an extended period.

Global Distribution of Protein Powder

Protein powder has gained popularity worldwide, leading to its widespread distribution. Manufacturers carefully plan and execute logistics to ensure their products reach consumers efficiently and securely.

Global distribution networks enable protein powders to be available in various countries, both through physical retail outlets and online platforms. This accessibility allows individuals from different regions to enjoy the benefits of protein supplementation.

The Environmental Impact of Protein Powder Production

While protein powder offers numerous benefits, it is essential to consider its environmental impact. Sustainable practices in the manufacturing process can help mitigate this impact and preserve the health of our planet.

Sustainability Concerns in the Industry

One major concern is the sourcing of raw materials. For instance, the production of whey protein generates significant amounts of whey by-products, which, if improperly managed, can lead to environmental pollution. However, some companies have implemented innovative solutions to recycle and utilize these by-products effectively.

Additionally, the use of plant-based proteins, such as soy or pea, provides a more sustainable alternative as they require fewer resources and have a lower carbon footprint compared to animal-based proteins.

Steps Towards Greener Production

Through continuous research and development, manufacturers are making strides towards greener production methods. These include optimizing energy consumption, implementing recycling programs, and reducing packaging waste.

Furthermore, consumer awareness and demand for sustainable products are driving manufacturers to prioritize eco-friendly practices and invest in renewable energy sources.

Overall, understanding how protein powder is made sheds light on the intricate processes involved in its production. From sourcing the raw materials to quality control, packaging, and the environmental impact, each step plays a vital role in delivering a high-quality and sustainable product. Whether you're an athlete, fitness enthusiast, or simply looking to boost your protein intake, protein powder provides a convenient and effective way to meet your nutritional needs.