How Do You Manufacture Nutritional Supplements

How Do You Manufacture Nutritional Supplements

Nutritional supplements play a vital role in supporting overall health and well-being. From providing essential nutrients to targeted health benefits, these supplements are widely used by people of all ages. Have you ever wondered how these supplements are manufactured? In this article, we will delve into the fascinating process behind the production of nutritional supplements, from understanding the basics to regulatory compliance, quality control measures, and packaging guidelines.

Understanding the Basics of Nutritional Supplements

In order to truly grasp the manufacturing process of nutritional supplements, it is important to have a solid understanding of what they actually are. Nutritional supplements are products that are designed to supplement the diet and provide essential nutrients, such as vitamins, minerals, amino acids, and herbal extracts. They are typically available in various forms, including capsules, tablets, powders, and liquids. These supplements are not intended to replace a balanced diet, but rather to fill gaps in nutrition or provide specific benefits for individuals with certain health concerns.

When it comes to nutritional supplements, it's important to understand that they are not regulated in the same way as prescription medications. While prescription drugs undergo rigorous testing and evaluation before they can be marketed, nutritional supplements are regulated under the Dietary Supplement Health and Education Act (DSHEA) of 1994. This means that manufacturers are responsible for ensuring the safety and labeling of their products, but they do not need to provide evidence of efficacy before they can be sold.

Defining Nutritional Supplements

Nutritional supplements can be categorized into several types, such as multivitamins, single-ingredient supplements, and specialized formulations. Multivitamins often contain a combination of essential vitamins and minerals that support overall health. They are designed to provide a broad range of nutrients that may be lacking in a person's diet. Single-ingredient supplements, on the other hand, focus on providing a high dose of a specific nutrient, such as Vitamin C or calcium. These supplements are often used to address specific deficiencies or to support certain bodily functions.

Specialized formulations are designed for specific health conditions or targeted benefits. For example, there are supplements formulated to support joint health, immune function, or cognitive performance. These formulations often contain a combination of nutrients, herbs, or other natural ingredients that have been shown to have specific health benefits. It's important to note that while these specialized formulations can be beneficial for certain individuals, they may not be necessary or suitable for everyone.

Importance of Nutritional Supplements

Nutritional supplements are an important addition to a healthy lifestyle and can help bridge nutritional gaps. Factors such as poor dietary choices, hectic schedules, and certain health conditions can lead to inadequate nutrient intake. By taking nutritional supplements, individuals can ensure they are getting the necessary nutrients to support their overall health and well-being.

However, it's important to remember that nutritional supplements should not be seen as a substitute for a balanced diet. While they can provide additional nutrients, they cannot replicate the complex interactions and synergistic effects of whole foods. A healthy diet should always be the foundation of good nutrition, with supplements used to complement and enhance it.

Furthermore, it's crucial to consult with a healthcare professional before starting any new supplement regimen. They can help determine if you have any specific nutrient deficiencies or health concerns that may benefit from supplementation. They can also provide guidance on the appropriate dosage and potential interactions with medications or existing health conditions.

In conclusion, nutritional supplements play a valuable role in supporting overall health and well-being. They can help fill nutritional gaps and provide targeted benefits for specific health concerns. However, it's important to approach supplementation with knowledge and caution, understanding that they are not a substitute for a healthy diet and that individual needs may vary. With the guidance of a healthcare professional, nutritional supplements can be a valuable addition to a balanced lifestyle.

The Manufacturing Process of Nutritional Supplements

The manufacturing process of nutritional supplements involves several important steps that ensure the final product is safe, effective, and of high quality. Let's take a closer look at these steps:

Raw Material Selection

The first step in the manufacturing process is the careful selection of raw materials. High-quality ingredients are essential for producing potent and safe supplements. Manufacturers must source ingredients from reliable suppliers and conduct thorough quality checks to ensure the purity, potency, and safety of the raw materials.

During the raw material selection process, manufacturers consider various factors such as the origin of the ingredients, their nutritional composition, and any potential allergens. They also evaluate the suppliers' manufacturing practices, quality control procedures, and adherence to regulatory standards. By carefully selecting raw materials, manufacturers can ensure that the supplements they produce meet the highest quality standards.

Formulation Development

Once the raw materials are selected, the next step is formulation development. This involves determining the ideal combination and proportions of ingredients to achieve the desired nutritional profile and health benefits. Formulation development requires extensive research, scientific expertise, and adherence to regulatory guidelines.

During the formulation development stage, manufacturers work closely with nutritionists, scientists, and regulatory experts to create a well-balanced and effective formula. They consider factors such as the bioavailability of nutrients, potential interactions between ingredients, and the stability of the final product. Through meticulous testing and analysis, manufacturers ensure that the formulated supplements deliver the intended health benefits without any adverse effects.

Production Methods

After the formulation is finalized, the production process begins. There are various methods used for supplement production, such as encapsulation, tableting, and powders. These methods involve precise measurements, mixing, and blending of ingredients to create the final product. Advanced technologies and quality control measures are employed at every stage to ensure consistency and uniformity in the manufacturing process.

During the production process, manufacturers follow strict protocols to maintain the integrity and quality of the supplements. They use specialized equipment and machinery to accurately measure and combine the ingredients. For encapsulation, the ingredients are carefully filled into capsules of the appropriate size. In tableting, the ingredients are compressed into tablets using high-pressure machines. Powders are created by blending the ingredients and then carefully packaging them.

Throughout the production process, manufacturers conduct regular quality control checks to ensure that the supplements meet the required specifications. These checks include testing for potency, purity, dissolution, and microbiological contamination. By implementing robust quality control measures, manufacturers can guarantee that each batch of supplements is safe, effective, and consistent in its nutritional content.

Quality Control in Supplement Manufacturing

Ensuring the safety and efficacy of nutritional supplements is of utmost importance. To achieve this, manufacturers follow stringent quality control measures throughout the manufacturing process. Let's explore two key aspects of quality control in supplement manufacturing:

Testing for Purity and Potency

Before the final product reaches consumers, it undergoes rigorous testing to ensure its purity and potency. This involves analyzing the product for contaminants, such as heavy metals, pesticides, and microbial contaminants. The presence of these contaminants can pose serious health risks to consumers, so manufacturers take great care in conducting thorough testing.

One of the primary tests conducted is for heavy metals. Heavy metals, such as lead, mercury, and arsenic, can find their way into supplements through various sources, including the raw materials used in production. These metals can accumulate in the body over time and have detrimental effects on health. To prevent this, manufacturers employ advanced analytical techniques, such as inductively coupled plasma mass spectrometry (ICP-MS), to detect even trace amounts of heavy metals.

Pesticide residues are another concern in supplement manufacturing. Pesticides are commonly used in agriculture to protect crops from pests and diseases. However, if not properly monitored, these residues can end up in the raw materials used for supplement production. To ensure the safety of supplements, manufacturers employ methods like gas chromatography-mass spectrometry (GC-MS) to detect and quantify pesticide residues.

Microbial contaminants, such as bacteria, yeast, and mold, can also compromise the safety of supplements. These contaminants can proliferate during the manufacturing process or contaminate the raw materials. To address this, manufacturers conduct microbial testing using techniques like plate counting and polymerase chain reaction (PCR) to identify and quantify any microbial contaminants present.

Additionally, potency testing is conducted to verify that the product contains the stated amount of active ingredients and meets established quality standards. This is crucial to ensure that consumers receive the intended benefits from the supplements they take. Manufacturers use various analytical methods, such as high-performance liquid chromatography (HPLC) and spectrophotometry, to accurately determine the concentration of active ingredients in the final product.

Ensuring Consistency in Production

Consistency is crucial when it comes to supplement manufacturing. Manufacturers implement quality control measures to ensure that each batch of supplements is produced with the same high standards. This involves strict adherence to standardized operating procedures, regular equipment maintenance, and ongoing monitoring and verification of critical manufacturing parameters.

Standardized operating procedures (SOPs) are comprehensive documents that outline the step-by-step instructions for each stage of the manufacturing process. These SOPs cover everything from raw material handling and equipment setup to product formulation and packaging. By following these procedures meticulously, manufacturers can minimize variations in the final product and maintain consistency.

Regular equipment maintenance is another important aspect of ensuring consistency in supplement manufacturing. Equipment used in the production process, such as mixers, encapsulation machines, and packaging lines, need to be properly maintained to ensure optimal performance. This includes routine cleaning, calibration, and preventive maintenance to prevent breakdowns and ensure accurate and reliable production.

In addition to SOPs and equipment maintenance, ongoing monitoring and verification of critical manufacturing parameters are essential. This involves continuously monitoring variables such as temperature, humidity, pressure, and mixing times to ensure that they remain within specified ranges. Manufacturers use advanced monitoring systems and automated controls to track these parameters in real-time and make adjustments as needed to maintain consistency.

Furthermore, manufacturers conduct regular audits and inspections to assess the effectiveness of their quality control measures. These audits may be performed by internal quality assurance teams or external regulatory agencies. By conducting thorough audits, manufacturers can identify any potential issues or areas for improvement and take corrective actions to maintain the highest standards of quality control.

Regulatory Compliance in Supplement Manufacturing

The manufacturing of nutritional supplements is subject to stringent regulations to protect consumer safety and ensure product quality. Two important regulatory aspects to consider are:

Understanding Dietary Supplement Health and Education Act (DSHEA)

The DSHEA is a federal law in the United States that sets forth regulations for dietary supplements. It outlines labeling requirements, ingredient safety, and manufacturing practices. Compliance with the DSHEA is essential to ensure that nutritional supplements meet legal standards and are accurately labeled.

Compliance with Good Manufacturing Practices (GMP)

GMP refers to a set of quality assurance guidelines that ensure the consistent production and control of dietary supplements. These guidelines cover various aspects, including personnel qualifications, facility standards, raw material testing, documentation practices, and product labeling. Compliance with GMP helps maintain a high level of quality and safety in supplement manufacturing.

Packaging and Labeling of Nutritional Supplements

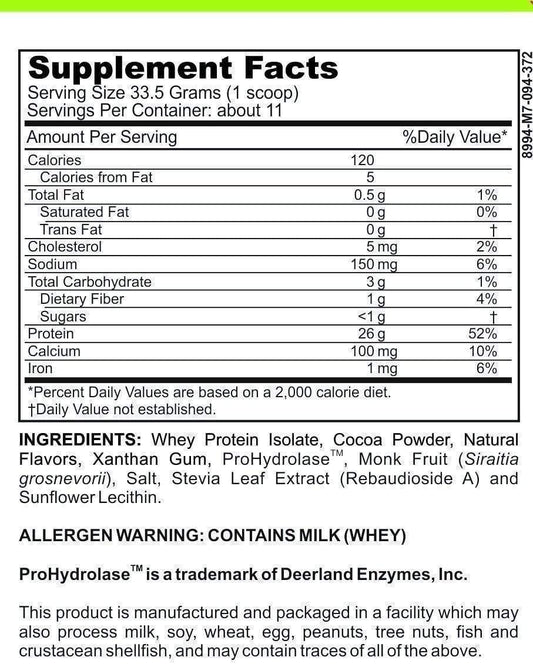

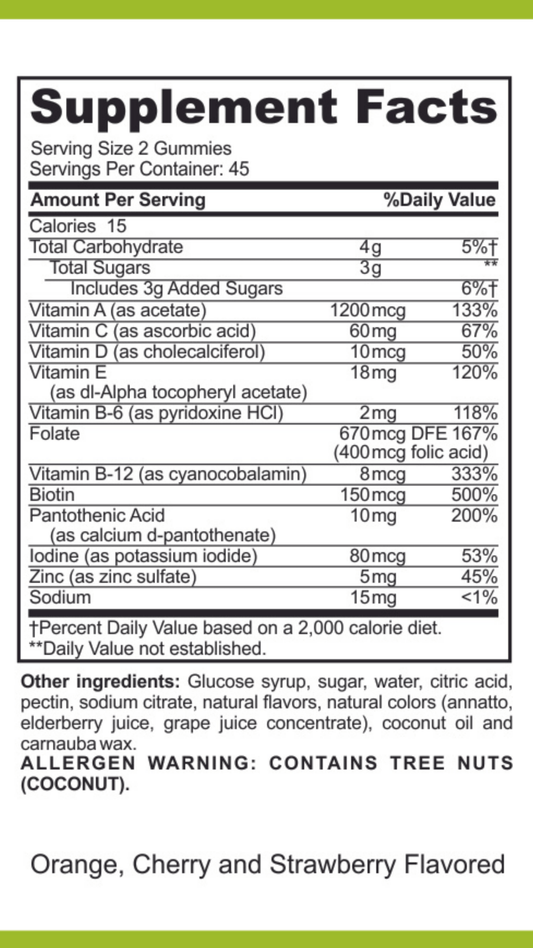

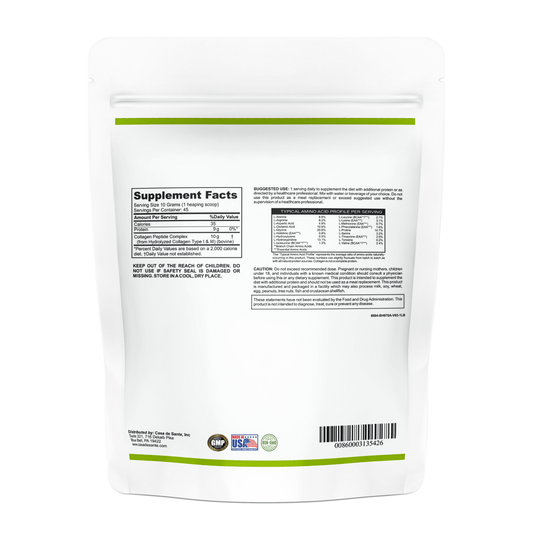

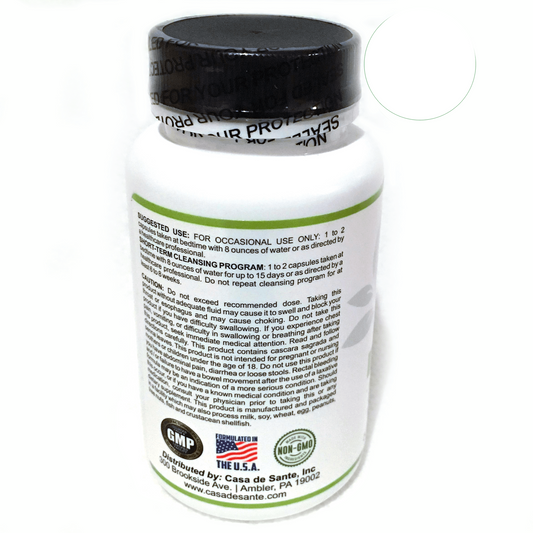

Once the manufacturing process is complete, the final step is packaging and labeling the nutritional supplements. It is crucial to choose the right packaging materials to protect the product from moisture, light, and oxygen. Additionally, proper labeling is vital to provide consumers with accurate information about the product, including ingredients, dosage instructions, and any potential allergens or warnings.

Choosing the Right Packaging

When selecting packaging materials for nutritional supplements, manufacturers consider factors such as product stability, shelf life, and customer convenience. Common packaging options include bottles, blister packs, sachets, and tubs. Each option has its own advantages and is chosen based on the specific requirements of the product.

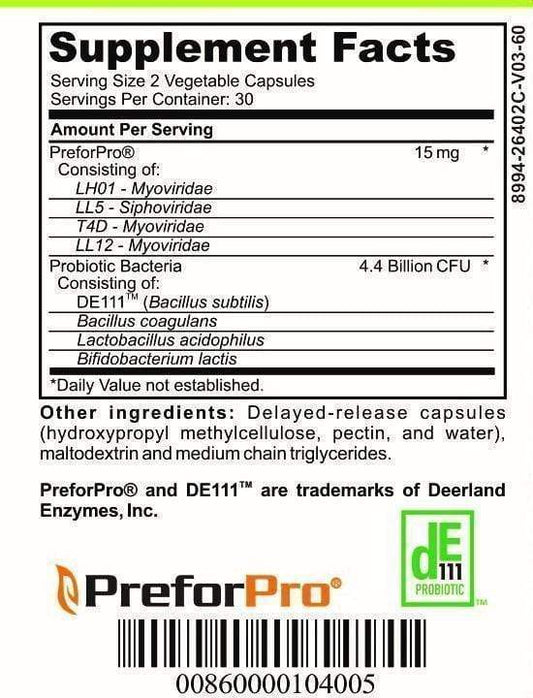

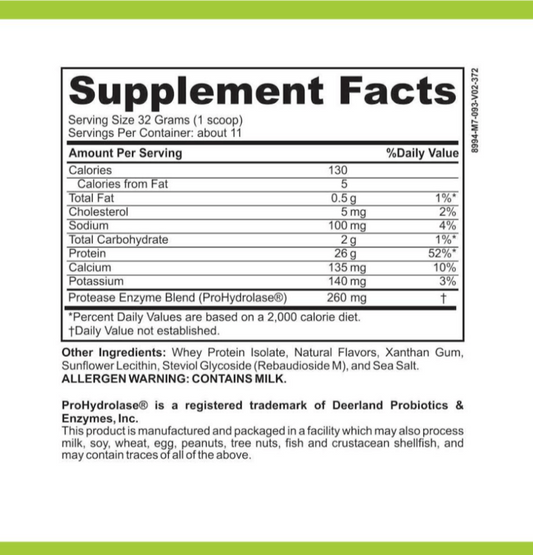

Labeling Requirements and Best Practices

Accurate and informative labeling is crucial for nutritional supplements. Labels should clearly state the name of the product, quantity of active ingredients, suggested dosage, and any health claims. It is also important to include allergen information, manufacturer contact details, and relevant legal disclaimers. Following these labeling requirements and best practices ensures that consumers have access to the necessary information to make informed choices.

In conclusion, the manufacturing process of nutritional supplements is a meticulous and regulated endeavor. From raw material selection to quality control measures, adherence to regulatory compliance, and proper packaging and labeling, every step is crucial in ensuring the production of safe and effective products. By understanding this process, consumers can have confidence in the nutritional supplements they incorporate into their daily wellness routine.