Are Now Vitamins Manufactured In Usa

Are Now Vitamins Manufactured In Usa

In recent years, there has been a growing interest in the origin and manufacturing process of various products, including dietary supplements. One particular brand that often comes to mind is Now Vitamins. As consumers become more aware of the importance of knowing where their supplements are made, it's essential to delve into the manufacturing practices of Now Vitamins and understand whether they are indeed manufactured in the USA.

Understanding the Manufacturing Process of Now Vitamins

Now Vitamins takes pride in its transparent approach to production, ensuring that their customers have access to high-quality supplements that meet stringent standards. The manufacturing process consists of several key steps to guarantee the safety and efficacy of their products.

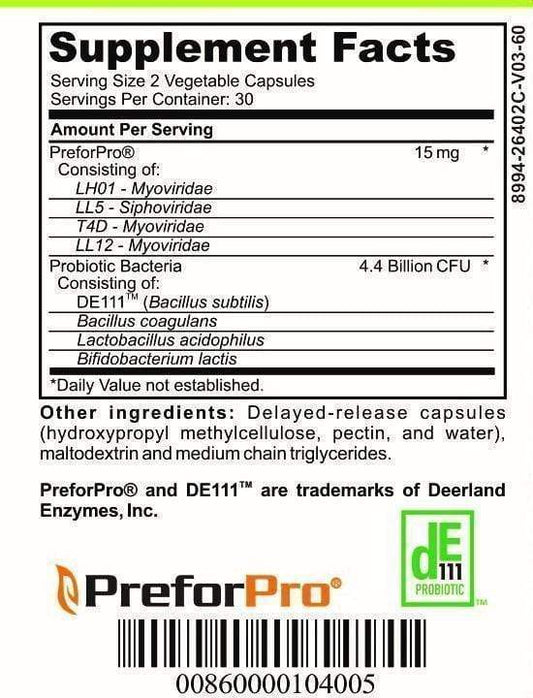

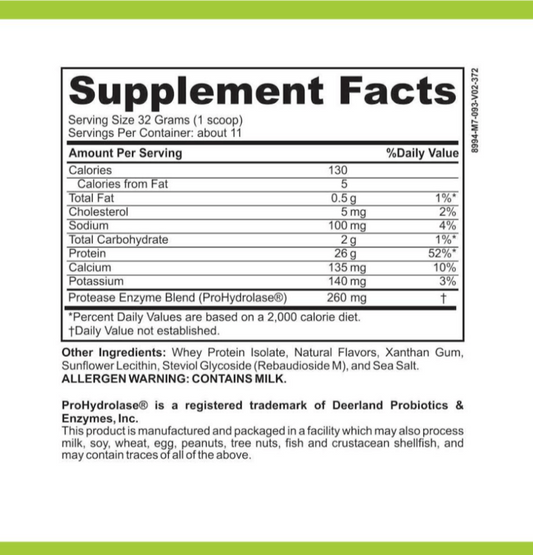

At Now Vitamins, the manufacturing process begins with the careful selection of key ingredients. These ingredients are sourced from reputable suppliers who adhere to strict quality standards. The brand prioritizes using premium ingredients that are scientifically proven and rigorously tested for purity and potency. This commitment to ingredient quality sets Now Vitamins apart from other supplement manufacturers.

Once the ingredients are received, they undergo a series of rigorous quality control checks. Now Vitamins has implemented comprehensive quality control measures at every stage of production. Their state-of-the-art facilities are equipped with advanced technology to monitor and maintain the quality of their products.

The manufacturing process at Now Vitamins is carried out by highly trained and skilled professionals who follow strict protocols to ensure consistency and accuracy. Each step of the process is carefully monitored to prevent any deviations from the desired standards.

After the initial manufacturing process, Now Vitamins conducts regular third-party testing to ensure that their supplements meet the highest standards of purity and potency. This additional layer of quality control provides further assurance to customers that they are getting a safe and effective product.

Once the products pass all quality control checks, they are carefully packaged and labeled. Now Vitamins pays attention to every detail, ensuring that their products are properly sealed and labeled with accurate information.

It is worth noting that Now Vitamins also prioritizes sustainability in their manufacturing process. They strive to minimize waste and reduce their environmental impact by implementing eco-friendly practices wherever possible.

In conclusion, the manufacturing process of Now Vitamins is a meticulous and transparent journey that prioritizes ingredient quality, rigorous quality control measures, and sustainability. By following these strict protocols, Now Vitamins ensures that their customers receive high-quality supplements that they can trust.

The Role of FDA in Regulating Vitamin Manufacturing

The United States Food and Drug Administration (FDA) plays a crucial role in regulating the manufacturing of vitamins and dietary supplements. The FDA sets guidelines and regulations that supplement manufacturers must adhere to in order to ensure the safety and quality of their products. This oversight is essential to protect consumers and promote public health.

Now, let's delve deeper into the FDA's guidelines for vitamin manufacturing and explore how Now Vitamins, a prominent player in the industry, complies with these regulations.

FDA Guidelines for Vitamin Manufacturing

The FDA has established comprehensive guidelines that govern the manufacturing of vitamins and dietary supplements. These guidelines outline the requirements for Good Manufacturing Practices (GMP), which encompass various aspects of production, including facility cleanliness, personnel training, and quality control.

Under these guidelines, supplement manufacturers like Now Vitamins are required to have a well-maintained facility that meets specific cleanliness standards. This includes regular cleaning and sanitization of equipment and production areas to prevent contamination. Additionally, personnel involved in the manufacturing process must undergo thorough training to ensure they understand and follow proper procedures.

Quality control is another crucial aspect of FDA guidelines. Manufacturers must implement rigorous testing and analysis procedures to verify the identity, purity, strength, and composition of their products. This ensures that consumers are getting what they expect from their vitamins and supplements.

Compliance of Now Vitamins with FDA Regulations

Now Vitamins takes FDA regulations seriously and consistently maintains compliance with these guidelines. Their manufacturing facilities undergo regular inspections to ensure that they meet and exceed the FDA's strict requirements. These inspections are conducted by FDA officials who assess the facility's adherence to GMP, including cleanliness, personnel training, and quality control measures.

By complying with FDA regulations, Now Vitamins demonstrates its commitment to producing safe and reliable supplements. This commitment extends beyond meeting the minimum requirements set by the FDA; it reflects a dedication to going above and beyond to ensure the highest standards of quality and safety.

Furthermore, Now Vitamins understands the importance of transparency and consumer trust. They provide detailed information about their manufacturing processes, sourcing of ingredients, and quality assurance practices on their website. This level of transparency allows consumers to make informed decisions and reinforces Now Vitamins' commitment to product safety and quality.

In conclusion, the FDA's role in regulating the manufacturing of vitamins and dietary supplements is vital for consumer protection. Now Vitamins, as a responsible industry player, adheres to these regulations and consistently maintains compliance. By doing so, they prioritize the safety and quality of their products, providing consumers with peace of mind when choosing Now Vitamins as their trusted supplement provider.

Economic Impact of Now Vitamins Manufacturing in the USA

The manufacturing of vitamins, including Now Vitamins, has a significant economic impact on the USA. Let's explore the positive implications that Now Vitamins' production has on both job creation and the overall economy.

Job Creation in the Vitamin Manufacturing Industry

Now Vitamins, being a prominent player in the vitamin manufacturing industry, contributes to job creation in the USA. Their manufacturing facilities employ skilled workers who contribute to the production and distribution of their high-quality supplements. Moreover, the demand for Now Vitamins' products also leads to indirect job creation in various sectors, such as packaging, transportation, and retail.

The employment opportunities provided by Now Vitamins not only benefit the workers but also have a ripple effect on the economy. The wages earned by these employees are spent on various goods and services, thereby stimulating other sectors of the economy. For example, a worker employed at Now Vitamins may spend their income on housing, groceries, and entertainment, which in turn supports jobs in the real estate, agriculture, and leisure industries.

Furthermore, Now Vitamins' commitment to quality and innovation necessitates a skilled workforce. As a result, the company invests in training programs and professional development opportunities for its employees. This investment not only enhances the skills and knowledge of the workers but also contributes to the overall human capital development in the country.

Contribution of Vitamin Manufacturing to the US Economy

Now Vitamins and other manufacturers in the industry contribute to the overall strength of the US economy. The production, distribution, and sales of vitamins generate substantial revenue for the country. This revenue stimulates economic growth, supports other industries, and ultimately improves the standard of living for the population.

One of the key ways in which Now Vitamins contributes to the US economy is through tax revenue. As a profitable business, Now Vitamins pays various taxes, including corporate income tax, property tax, and sales tax. These tax payments directly benefit the government, which can then allocate the funds towards public infrastructure, education, healthcare, and other essential services.

Moreover, Now Vitamins' manufacturing operations require raw materials and supplies, which are often sourced from local suppliers. This creates a positive ripple effect on the economy, as the demand for these inputs supports other businesses and industries. For example, the procurement of packaging materials from local suppliers helps sustain jobs in the packaging industry, while the purchase of machinery and equipment from domestic manufacturers supports the manufacturing sector.

Additionally, Now Vitamins' success in the market contributes to the country's export industry. The company's high-quality products are sought after by consumers not only in the USA but also in international markets. The export of Now Vitamins' supplements generates foreign exchange earnings, strengthens the balance of trade, and enhances the country's reputation as a producer of quality goods.

In conclusion, Now Vitamins' manufacturing operations have a far-reaching impact on the USA's economy. Through job creation, tax revenue, and support for other industries, the company contributes to economic growth and the overall well-being of the population. As Now Vitamins continues to thrive, its positive economic impact is likely to persist and expand, benefiting both the company and the nation as a whole.

Environmental Considerations in Vitamin Manufacturing

As sustainability becomes an increasingly important topic worldwide, it's crucial to examine the environmental considerations in the manufacturing process of vitamins, specifically in the case of Now Vitamins.

Vitamin manufacturing is a complex process that involves various stages, from sourcing raw materials to packaging the final product. Each step presents unique challenges and opportunities for environmental stewardship. Now Vitamins, a leading player in the industry, recognizes the importance of sustainable practices and has made significant efforts to minimize their environmental impact.

Sustainable Practices in Now Vitamins Production

Now Vitamins understands that sustainability is not just a buzzword but a responsibility. They have taken proactive measures to integrate sustainable practices into their manufacturing process, ensuring that their products are not only beneficial for consumers but also for the planet.

One of the ways Now Vitamins promotes sustainability is through the use of energy-efficient equipment. By investing in state-of-the-art machinery, they have significantly reduced their energy consumption, resulting in lower greenhouse gas emissions. This commitment to energy efficiency not only helps mitigate climate change but also reduces their operational costs.

In addition to energy efficiency, Now Vitamins has implemented measures to minimize water usage. Water scarcity is a pressing global issue, and the manufacturing industry is a significant contributor to water pollution and depletion. Now Vitamins recognizes this challenge and has adopted water-saving technologies and practices. Through the use of closed-loop systems and water recycling, they have significantly reduced their water consumption, ensuring that this precious resource is conserved for future generations.

Furthermore, waste management is a critical aspect of Now Vitamins' sustainability efforts. The production of vitamins can generate various types of waste, including packaging materials, byproducts, and unused raw materials. To address this issue, Now Vitamins has implemented advanced waste management systems. They prioritize waste reduction through recycling and repurposing, ensuring that as little waste as possible ends up in landfills. By actively seeking innovative solutions for waste management, Now Vitamins is setting an example for the industry and contributing to a cleaner and more sustainable environment.

Waste Management in Vitamin Manufacturing

Now Vitamins understands that waste management is not just about disposing of waste responsibly but also about preventing waste generation in the first place. They have implemented a comprehensive waste management strategy that focuses on minimizing waste production throughout the manufacturing process.

At Now Vitamins, waste reduction starts at the sourcing stage. They carefully select suppliers who share their commitment to sustainability and prioritize eco-friendly packaging materials. By choosing suppliers who use recyclable or biodegradable materials, Now Vitamins ensures that their products have a smaller environmental footprint from the very beginning.

During the manufacturing process, Now Vitamins employs rigorous quality control measures to minimize product defects. By ensuring that their products meet the highest standards, they reduce the likelihood of waste generation due to faulty or unusable items. Additionally, any raw materials that do not meet the quality requirements are repurposed or recycled whenever possible.

Now Vitamins also actively encourages their employees to participate in waste reduction initiatives. They provide training and education on waste management practices, empowering their workforce to identify opportunities for improvement and implement sustainable solutions. By fostering a culture of environmental responsibility, Now Vitamins ensures that waste reduction is a collective effort.

In conclusion, Now Vitamins is at the forefront of sustainable vitamin manufacturing. Through their commitment to energy efficiency, water conservation, and waste management, they demonstrate their dedication to environmental stewardship. By implementing these sustainable practices, Now Vitamins not only produces high-quality vitamins but also contributes to a healthier and more sustainable planet.

Future Trends in Vitamin Manufacturing

The landscape of vitamin manufacturing is continually evolving, driven by technological advancements and changing consumer preferences. Let's take a look at some future trends that may shape the industry, including the impact of globalization on vitamin manufacturing.

Technological Innovations in Vitamin Production

Rapid technological advancements are revolutionizing the way vitamins are manufactured. Innovations such as advanced extraction methods, encapsulation technologies, and improved packaging solutions are enhancing the efficiency, quality, and shelf life of vitamins. Now Vitamins, as an industry leader, remains at the forefront of these technological developments, ensuring that their customers have access to cutting-edge products.

The Impact of Globalization on Vitamin Manufacturing

Globalization has had a profound impact on various industries, including vitamin manufacturing. Many supplement companies, including Now Vitamins, source ingredients from different countries around the world. This global sourcing allows for a broader selection of high-quality ingredients and promotes cultural exchange. However, it also necessitates rigorous quality control measures to ensure the safety and authenticity of the ingredients used.

In conclusion, Now Vitamins is indeed manufactured in the USA. Their commitment to transparency, quality control, FDA compliance, and sustainability sets them apart in the industry. With their positive economic impact, environmental considerations, and anticipation of future trends, Now Vitamins continues to be a trusted and reliable provider of dietary supplements for health-conscious consumers worldwide.