What Is A Polyol

What Is A Polyol

Polyols are a class of compounds that are commonly used in various industries, including food, pharmaceuticals, and plastics. In this article, we will explore the basics of polyols, their different types, their role in the food industry, health implications, and their environmental impact.

Understanding the Basics of Polyols

Polyols, also known as sugar alcohols, are a type of carbohydrate that contain multiple hydroxyl groups (-OH). These hydroxyl groups are responsible for their sweet taste. Polyols are derived from sugars through various chemical processes, such as hydrogenation or fermentation.

When it comes to understanding polyols, it's important to delve deeper into their definition and chemical structure. Let's explore these aspects further.

Definition of Polyols

Polyols, in the context of chemistry, refers to compounds that have more than one hydroxyl (-OH) group. These compounds are commonly used as sugar substitutes due to their sweet taste but with reduced calorie content. Polyols have a lower glycemic index compared to traditional sugars, making them suitable for individuals with diabetes or those following a low-carbohydrate diet.

One of the key advantages of polyols is their ability to provide sweetness without causing a significant increase in blood sugar levels. This makes them a popular choice for individuals who want to satisfy their sweet tooth while managing their overall sugar intake.

The Chemical Structure of Polyols

The chemical structure of polyols is characterized by the presence of multiple hydroxyl groups. This property distinguishes them from other carbohydrates, such as monosaccharides or disaccharides, which typically have only one or two hydroxyl groups, respectively. The arrangement and number of hydroxyl groups in polyols determine their specific properties and applications.

It is fascinating to explore the diverse chemical structures of different polyols. For example, sorbitol, a commonly used polyol, has six hydroxyl groups, while xylitol has five. These variations in the chemical structure give each polyol its unique characteristics, such as sweetness intensity and solubility.

Moreover, the chemical structure of polyols also plays a crucial role in their applications. Polyols are widely used in the food industry as sweeteners, bulking agents, and humectants. They are also utilized in the production of various products, including chewing gum, candies, baked goods, and pharmaceuticals.

In conclusion, polyols are versatile compounds that offer a sweet taste without the high calorie content of traditional sugars. Their unique chemical structure, characterized by multiple hydroxyl groups, allows for various applications in the food and pharmaceutical industries. Understanding the basics of polyols provides valuable insights into their role as sugar substitutes and their potential benefits for individuals with specific dietary needs.

The Different Types of Polyols

Polyols come in various types, each with different chemical structures and properties. The three main types of polyols are sugar alcohols, polyether polyols, and polyester polyols. Let's explore each type in more detail.

Sugar Alcohols

Sugar alcohols are a group of polyols that are derived from sugars. They are widely used as sweeteners in sugar-free products and have gained popularity among individuals who are conscious of their sugar intake. Examples of sugar alcohols include xylitol, sorbitol, and erythritol.

Sugar alcohols are unique because they have a similar chemical structure to both sugars and alcohols. They are derived from the hydrogenation of sugars, which involves the addition of hydrogen atoms to the sugar molecule. This process results in the formation of a polyol with a sweet taste but with fewer calories than regular sugar.

One of the main advantages of sugar alcohols is that they do not cause a significant increase in blood sugar levels. This makes them a suitable alternative for individuals with diabetes or those following a low-carbohydrate diet. Additionally, sugar alcohols have a lower glycemic index compared to regular sugar, which means they have a slower and more gradual impact on blood sugar levels.

In addition to their use as sweeteners, sugar alcohols also have other properties that make them valuable in the food industry. For example, they have a cooling effect on the tongue, which is why they are often used in chewing gum and mint candies. Sugar alcohols also have a lower risk of tooth decay compared to regular sugar, making them a popular ingredient in oral care products such as toothpaste and mouthwash.

Polyether Polyols

Polyether polyols are a type of polyol that is commonly used in the production of polyurethane foams. These polyols are derived from the reaction between epoxides and alcohols. They have excellent flexibility, good abrasion resistance, and high load-bearing properties, making them suitable for various applications, including furniture, mattresses, and automotive components.

The production of polyether polyols involves the reaction of epoxides, such as propylene oxide or ethylene oxide, with a starter molecule, which is typically a multifunctional alcohol. This reaction results in the formation of a polyether polyol with a linear or branched structure.

Polyether polyols have a unique molecular structure that allows them to have exceptional properties. They have a high degree of flexibility, which makes them ideal for applications that require materials to bend or stretch without breaking. The flexibility of polyether polyols also contributes to their excellent abrasion resistance, making them suitable for products that undergo frequent wear and tear.

Another noteworthy property of polyether polyols is their high load-bearing capacity. This means that they can withstand heavy loads without deforming or losing their structural integrity. This property makes them valuable in the manufacturing of furniture, mattresses, and other products that need to support weight.

Polyester Polyols

Polyester polyols are polyols that are derived from the condensation reaction between a diol and a dicarboxylic acid. These polyols are commonly used in the production of rigid or semi-rigid polyurethane foams. They offer good thermal stability and excellent mechanical properties, making them suitable for insulation materials, adhesives, and coatings.

The production of polyester polyols involves the reaction between a diol, such as ethylene glycol or propylene glycol, and a dicarboxylic acid, such as adipic acid or phthalic acid. This reaction results in the formation of a polyester polyol with a linear or branched structure.

One of the key advantages of polyester polyols is their thermal stability. They can withstand high temperatures without degrading or losing their properties, making them suitable for applications that require heat resistance, such as insulation materials and coatings.

In addition to their thermal stability, polyester polyols also offer excellent mechanical properties. They have high tensile strength, which means they can withstand stretching or pulling forces without breaking. This property makes them valuable in the production of adhesives and sealants that require strong bonding capabilities.

Furthermore, polyester polyols have good chemical resistance, which means they can withstand exposure to various chemicals without undergoing significant degradation. This property makes them suitable for applications that involve contact with harsh chemicals, such as industrial coatings and chemical-resistant materials.

The Role of Polyols in Food Industry

Polyols have numerous applications in the food industry, primarily as sugar substitutes and bulking agents. Let's explore their role further.

Polyols, also known as sugar alcohols, are a group of low-calorie sweeteners that are commonly used in the production of sugar-free products. They provide a sweet taste without significantly affecting blood sugar levels, making them an ideal choice for individuals with diabetes or those looking to reduce their sugar consumption.

In addition to their role as sugar substitutes, polyols also offer various benefits in baking. When used in baking, polyols contribute to the texture, moisture, and sweetness of baked goods. They can help create soft and moist cakes, cookies, and bread, making them a popular ingredient among bakers.

Polyols in Sugar-Free Products

Polyols are extensively used in the production of sugar-free products, such as chewing gums, candies, and desserts. They provide a sweet taste without significantly affecting blood sugar levels. Moreover, polyols have lower caloric content compared to traditional sugars, making them an attractive alternative for individuals who want to reduce their sugar consumption.

One of the key advantages of using polyols in sugar-free products is their ability to mimic the taste and texture of sugar. This allows manufacturers to create sugar-free versions of popular treats without compromising on flavor. Whether it's a sugar-free chocolate bar or a sugar-free ice cream, polyols play a vital role in ensuring that these products are enjoyable for consumers.

Furthermore, polyols have a lower glycemic index compared to sugars, which means they have a minimal impact on blood sugar levels. This makes them a suitable choice for individuals with diabetes or those following a low-carbohydrate diet.

The Benefits of Polyols in Baking

Polyols also play a crucial role in baking. They contribute to the texture, moisture, and sweetness of baked goods. By replacing traditional sugars with polyols, bakers can create products that are suitable for individuals with diabetes or those looking to reduce their sugar intake. Polyols also have a cooling effect, making them a popular ingredient in sugar-free chewing gums.

When used in baking, polyols can help retain moisture in the final product, resulting in soft and moist textures. They also have a lower tendency to crystallize compared to traditional sugars, which can improve the shelf life of baked goods. Additionally, polyols have a lower caloric content, making them a preferred choice for individuals who are conscious of their calorie intake.

Moreover, polyols have the ability to enhance the flavor of baked goods. They provide a subtle sweetness that can complement other ingredients, such as fruits, nuts, and spices. This versatility allows bakers to experiment with different flavors and create unique and delicious treats.

In conclusion, polyols have become an integral part of the food industry, particularly in the production of sugar-free products and baking. Their ability to provide sweetness without the negative effects of traditional sugars makes them a valuable ingredient for individuals with specific dietary needs. Whether it's in sugar-free candies, desserts, or baked goods, polyols offer a sweet solution for those looking to enjoy their favorite treats while maintaining a balanced and healthy lifestyle.

Health Implications of Polyols

While polyols offer several benefits, it is essential to consider their potential health implications. Let's explore the impact of polyols on diabetes, dental health, and their potential side effects.

Polyols and Diabetes

Due to their lower glycemic index, polyols are often used as sugar substitutes in diabetic-friendly products. They have a minimal impact on blood sugar levels compared to traditional sugars. However, it is still necessary for individuals with diabetes to monitor their overall carbohydrate intake, including polyols, to maintain stable blood sugar levels.

Polyols and Dental Health

Polyols are considered tooth-friendly sweeteners. They do not contribute to tooth decay like sugars do. In fact, some polyols, such as xylitol, have been shown to have a protective effect against dental caries. Chewing gums containing polyols can stimulate saliva production and help maintain oral health.

Potential Side Effects of Polyols

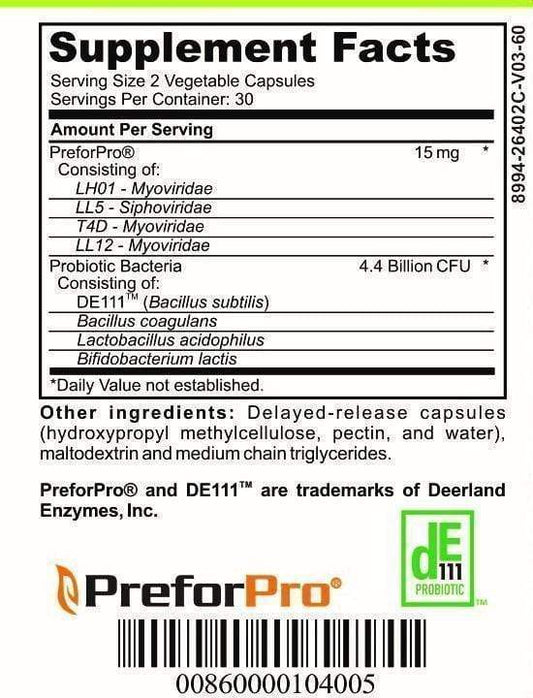

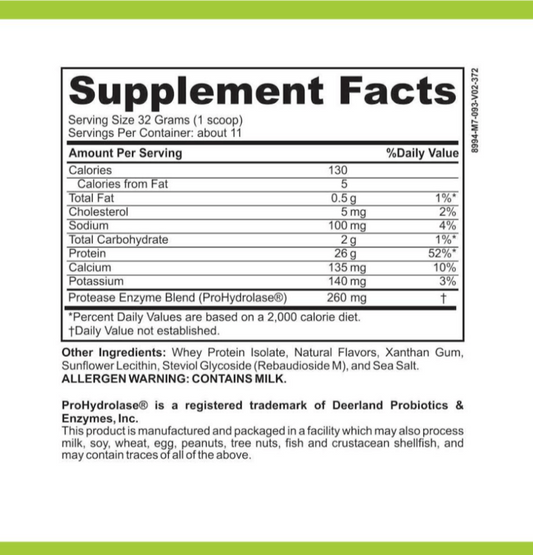

Consuming excessive amounts of polyols can cause gastrointestinal discomfort, such as bloating, gas, and diarrhea. This can occur because polyols are not completely absorbed in the small intestine and can pull water into the large intestine. It is important to consume polyols in moderation to avoid these side effects.

Environmental Impact of Polyols

Polyols also have environmental implications, particularly in the production of biodegradable plastics and the sustainability of their production processes.

Polyols in Biodegradable Plastics

Polyols play a significant role in the production of biodegradable plastics. These plastics offer an environmentally friendly alternative to traditional plastics derived from fossil fuels. Polyols derived from renewable sources can contribute to the development of sustainable plastics that degrade more easily, reducing pollution and waste accumulation.

Sustainability of Polyol Production

Efforts are being made to improve the sustainability of polyol production processes. This includes reducing energy consumption, minimizing waste generation, and utilizing renewable raw materials. By adopting sustainable practices, the environmental impact of polyol production can be reduced, contributing to a more sustainable future.

In conclusion, polyols are versatile compounds that find applications in various industries. They come in different types, each with unique properties and uses. In the food industry, polyols serve as sugar substitutes and bulking agents in sugar-free products. While they offer benefits such as reduced calorie content and tooth-friendly properties, it is crucial to consume polyols in moderation to avoid potential side effects. Moreover, polyols also have an environmental impact, with their potential use in biodegradable plastics and sustainable production processes. Understanding the basics