The Role of Enzymes in Food Products: Enhancing Quality and Nutrition

The Role of Enzymes in Food Products: Enhancing Quality and Nutrition

In the complex world of food production, enzymes stand as silent yet powerful catalysts that transform our everyday foods in countless ways. These biological molecules accelerate chemical reactions without being consumed themselves, making them invaluable tools in the food industry. From the bread we eat at breakfast to the cheese on our dinner plates, enzymes are working behind the scenes to enhance flavor, improve texture, and even boost nutritional content.

The strategic application of enzymes in food processing has revolutionized how manufacturers develop products that meet consumer demands for quality, nutrition, and sustainability. As natural protein molecules, enzymes offer food producers a way to create cleaner labels while still achieving the functionality needed for modern food production.

Understanding Food Enzymes: Nature's Catalysts

Enzymes are specialized proteins that act as biological catalysts, dramatically increasing the rate of specific chemical reactions without being consumed in the process. In food systems, they facilitate transformations that would otherwise take too long or require harsh processing conditions. What makes enzymes particularly valuable is their specificity—each enzyme typically catalyzes only one type of reaction or acts on a specific substrate.

The food industry utilizes enzymes from three primary sources: plants (like papain from papaya), animals (such as rennet from calves), and microorganisms (including bacteria and fungi). Today, most commercial food enzymes are produced through fermentation using carefully selected and often genetically optimized microorganisms, allowing for more sustainable and efficient production.

How Enzymes Function in Food Systems

At their core, enzymes work by lowering the activation energy required for chemical reactions. In food applications, this translates to breaking down complex molecules into simpler forms or building new compounds from smaller components. For instance, proteases break down proteins into peptides and amino acids, while amylases convert starches into simpler sugars.

The activity of enzymes depends on several factors, including temperature, pH, water activity, and the presence of inhibitors or activators. Food manufacturers carefully control these parameters to optimize enzyme performance during processing. Some processes require enzymes to work continuously, while others need enzyme activity to stop at a specific point—achieved through techniques like heat inactivation or pH adjustment.

Classification of Food Enzymes

Food enzymes are typically classified based on the reactions they catalyze. Major categories include hydrolases (which break down compounds by adding water), oxidoreductases (which catalyze oxidation-reduction reactions), transferases (which move functional groups between molecules), and isomerases (which rearrange atoms within molecules). Understanding these classifications helps food scientists select the right enzyme for specific applications and predict how they'll behave in different food matrices.

Enzymes in Baking: The Science Behind the Perfect Loaf

The transformation of flour, water, yeast, and salt into a crusty, aromatic loaf of bread involves a complex series of enzymatic reactions. While flour naturally contains enzymes like amylases and proteases, commercial bakers often supplement with additional enzymes to ensure consistency and quality, especially when working with flours that vary in enzymatic activity.

Amylases play a starring role by breaking down starch into maltose and other fermentable sugars that feed yeast, driving fermentation and leavening. This not only helps the dough rise but also contributes to the development of flavors and the golden-brown crust through Maillard reactions during baking.

Improving Texture and Shelf Life

Xylanases have become increasingly important in modern baking, as they modify the pentosans (complex carbohydrates) in flour, improving dough handling properties and creating a more uniform crumb structure. Meanwhile, lipases modify fats in the dough, strengthening the gluten network and improving volume and texture.

Perhaps most impressive is the role of enzymes in extending shelf life. Certain amylases can reduce the rate of bread staling by modifying starch structures, keeping bread softer longer without the need for chemical preservatives. Glucose oxidase creates stronger dough through oxidative gelation of gluten proteins, resulting in better gas retention and improved texture in the final product.

Gluten Modification and Specialty Products

For consumers with gluten sensitivities, proteases can partially degrade gluten proteins, making products more digestible for some individuals (though not safe for those with celiac disease). The strategic use of these enzymes allows bakers to create products with reduced gluten content while maintaining acceptable texture and mouthfeel.

In specialty baking, asparaginase has gained attention for its ability to reduce acrylamide formation in baked goods. By converting asparagine to aspartic acid before baking, this enzyme helps minimize the formation of this potential carcinogen during high-temperature baking, addressing an important food safety concern.

Dairy Processing: Enzymatic Transformations

The dairy industry relies heavily on enzymes, with cheese production standing as perhaps the oldest and most recognized enzymatic food process. Rennet, containing the enzyme chymosin, has been used for thousands of years to coagulate milk by cleaving a specific bond in casein proteins, initiating the transformation of liquid milk into solid curds.

Today's cheese makers have access to a variety of coagulants, including traditional animal rennet, microbial rennet alternatives, and recombinant chymosin produced through fermentation. These options provide flexibility in creating different cheese characteristics while addressing vegetarian and religious dietary restrictions.

Lactose Reduction and Digestibility

Lactose intolerance affects a significant portion of the global population, creating demand for lactose-reduced dairy products. Lactase (β-galactosidase) hydrolyzes lactose into glucose and galactose, creating sweeter-tasting milk products that are digestible by those lacking sufficient natural lactase. This enzyme has enabled the development of an entire category of lactose-free dairy products that retain the nutritional benefits of milk without the digestive discomfort for sensitive individuals.

Beyond lactose reduction, proteases can be used to pre-digest milk proteins, creating hypoallergenic infant formulas and improving protein digestibility in various dairy products. These enzymatically modified proteins often have enhanced functional properties as well, improving texture in products like yogurt and ice cream.

Fruit Juices and Beverages: Clarity and Quality

The crystal-clear apple juice or perfectly transparent grape juice on store shelves owes its appearance to enzymatic processing. Pectinases break down pectin—a complex polysaccharide that causes cloudiness and increased viscosity in fruit juices. By degrading these compounds, manufacturers can produce clear juices that meet consumer expectations for appearance while improving filtration efficiency during processing.

Beyond clarity, enzymes contribute to juice yield and quality. Cellulases and hemicellulases break down plant cell walls, releasing more juice during pressing and extracting additional flavor compounds, colors, and nutrients from fruit pulp. This not only improves production economics but can enhance the sensory and nutritional profiles of the final product.

Flavor Enhancement and Sugar Reduction

Glycosidases have found application in releasing bound flavor compounds in fruit juices and wine. Many fruits contain flavor molecules attached to sugar molecules, rendering them non-volatile and undetectable by smell. By cleaving these bonds, glycosidases can enhance aroma and flavor without adding any ingredients, creating more vibrant sensory experiences.

In the era of sugar reduction, glucose oxidase and catalase systems can be used to remove glucose from fruit juices, reducing caloric content while maintaining sweetness through the naturally present fructose. This enzymatic approach to sugar reduction offers a clean-label alternative to artificial sweeteners or traditional sugar-reduction methods.

Nutritional Enhancement Through Enzymatic Processing

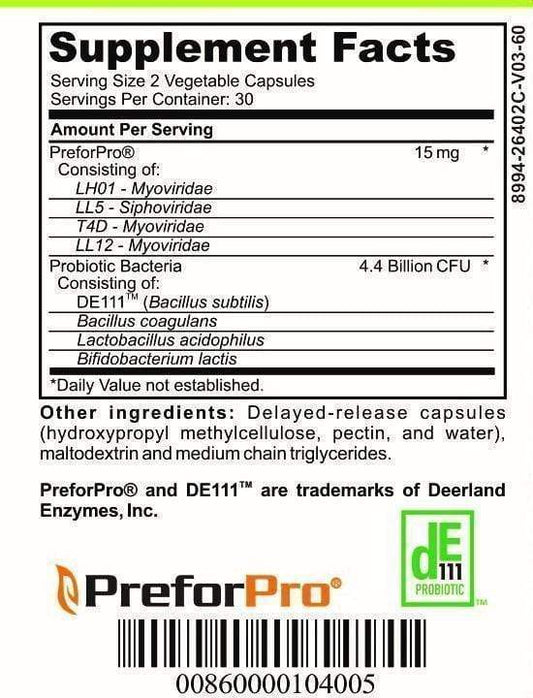

Beyond improving sensory qualities and processing efficiency, enzymes can significantly impact the nutritional value of foods. Phytases, for example, break down phytic acid—an anti-nutritional factor present in many grains and legumes that binds minerals like iron, zinc, and calcium, making them unavailable for absorption. By degrading phytate during food processing, these essential minerals become more bioavailable, enhancing the nutritional value of plant-based foods.

Similarly, enzymatic treatment can increase the content of bioactive compounds in certain foods. Fermentation involving specific enzymes can increase the content of isoflavones in soy products or generate bioactive peptides from milk proteins, potentially offering health benefits beyond basic nutrition.

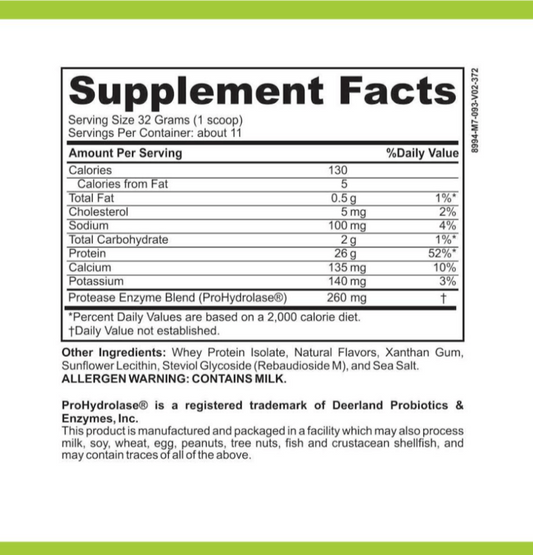

Protein Functionality and Alternative Proteins

As plant-based proteins gain popularity, enzymes are proving crucial in improving their functionality and acceptance. Proteases can modify plant proteins to reduce bitterness, improve solubility, and enhance gelation properties. This enzymatic tailoring helps create plant-based alternatives that more closely mimic the texture and mouthfeel of animal-derived products.

Transglutaminase, often called "meat glue," creates covalent bonds between protein molecules, improving texture in both traditional meat products and plant-based alternatives. This enzyme enables the creation of restructured meat products and helps plant proteins form more cohesive, meat-like structures in alternative protein products.

Future Directions: Enzymes and Sustainable Food Processing

As the food industry faces increasing pressure to adopt more sustainable practices, enzymes offer significant advantages. Enzymatic processes typically require less energy than traditional chemical or physical methods, as they work under mild conditions of temperature and pH. They also reduce the need for harsh chemicals in food processing, supporting cleaner labels and more environmentally friendly production methods.

Waste valorization represents another promising application, with enzymes being used to convert food processing by-products into valuable ingredients. Cellulosic materials from fruit and vegetable processing can be enzymatically converted into prebiotic fibers or fermentable sugars, creating a circular economy approach to food production.

Innovations on the Horizon

Advances in protein engineering and directed evolution are creating enzymes with enhanced stability, activity, and specificity for food applications. These tailored biocatalysts can work more efficiently under the specific conditions of food processing, opening new possibilities for enzymatic modifications that were previously impractical.

The integration of enzymes into active packaging represents another frontier, where enzymes incorporated into packaging materials can continue to improve food quality during storage and distribution. Lactase-containing packaging for milk, for example, could allow for in-package lactose hydrolysis, extending the concept of enzymatic processing beyond the factory.

As our understanding of food biochemistry deepens and enzyme technology advances, these remarkable biological catalysts will continue to transform how we produce, preserve, and enhance the foods that sustain us—improving quality, nutrition, and sustainability throughout the global food system.