How to Make Enzymes: A Step-by-Step Guide for Beginners

How to Make Enzymes: A Step-by-Step Guide for Beginners

Enzymes are remarkable biological catalysts that accelerate chemical reactions in living organisms. From digestion to fermentation, these protein molecules play crucial roles in countless natural processes. While commercial enzymes are readily available, making your own can be a rewarding project that offers both educational value and practical applications. This guide will walk you through the fundamentals of enzyme production at home, providing accessible methods for beginners while explaining the science behind each step.

Understanding Enzymes: The Basics

Before diving into enzyme production, it's important to understand what enzymes actually are. Enzymes are specialized proteins that act as biological catalysts, speeding up chemical reactions without being consumed in the process. Each enzyme has a specific function, determined by its unique three-dimensional structure, which allows it to bind to particular molecules (substrates) and facilitate their transformation.

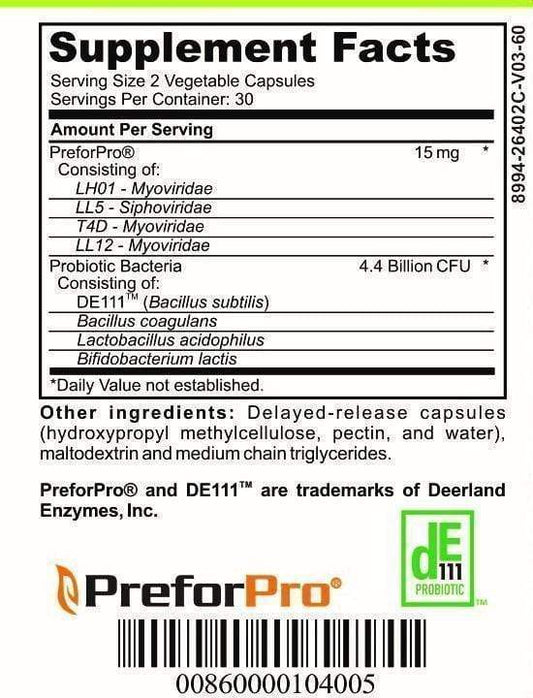

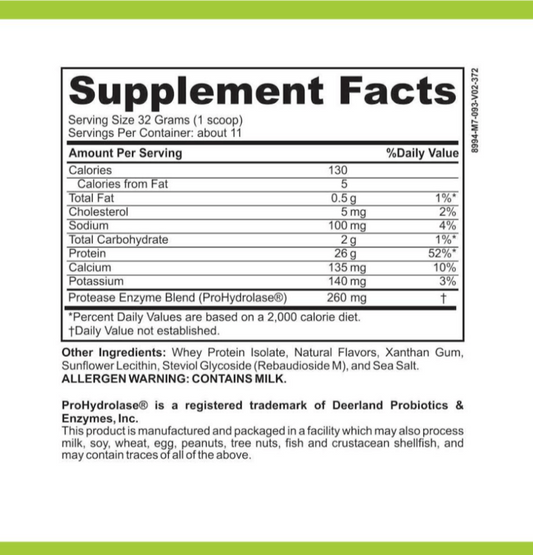

In nature, enzymes are responsible for countless essential processes: amylase breaks down starches in your mouth, protease digests proteins in your stomach, and lipase processes fats in your intestines. Beyond digestion, enzymes enable fermentation, detoxification, and virtually every metabolic process in living organisms.

Common Types of Homemade Enzymes

For beginners, several types of enzymes are relatively straightforward to produce at home. Digestive enzymes from fruits like papaya (containing papain) and pineapple (containing bromelain) can be extracted for use in meat tenderizers or digestive aids. Fermentation enzymes can be cultivated through simple processes involving beneficial bacteria and yeasts. Cleaning enzymes, derived from citrus peels or produced through fermentation, offer natural alternatives to harsh chemical cleaners.

The beauty of homemade enzyme production lies in its accessibility—many of the ingredients needed are common kitchen items, and the processes often mimic traditional food preparation techniques that have been used for generations across different cultures.

Essential Equipment and Ingredients

Creating enzymes at home doesn't require sophisticated laboratory equipment. Most of what you'll need is likely already in your kitchen or can be easily obtained from local stores. This accessibility makes enzyme production an approachable project for beginners interested in biotechnology or sustainable living practices.

Basic Equipment

To get started, gather these essential tools: glass jars with tight-fitting lids (avoid metal as it can react with fermenting ingredients), a digital kitchen scale for accurate measurements, pH test strips to monitor acidity levels, cheesecloth or fine mesh strainers for filtering, and non-metallic utensils for mixing and handling. A thermometer is also helpful for monitoring fermentation temperatures, as enzymes are sensitive to temperature fluctuations.

While not strictly necessary, a blender or food processor can significantly streamline the preparation process, especially when working with fibrous fruits or vegetables. For more precise work, droppers or pipettes help with measuring liquid enzymes once they're produced.

Key Ingredients

The ingredients for enzyme production vary depending on the type you're making, but several components are commonly used. Fresh organic fruits and vegetables serve as enzyme sources—pineapple cores, papaya skins, and citrus peels are particularly rich in natural enzymes. Brown sugar or molasses provides food for beneficial microorganisms during fermentation. Filtered water creates the medium for extraction and fermentation, while sea salt can help prevent unwanted bacterial growth in some recipes.

For specialized enzyme projects, you might also use specific starter cultures like kefir grains or kombucha SCOBY, which contain beneficial bacteria and yeasts that produce enzymes during fermentation. These can be purchased online or obtained from other fermentation enthusiasts.

Safety Considerations

Before beginning any enzyme production, establish good hygiene practices. Always wash your hands thoroughly before handling ingredients, and ensure all equipment is properly cleaned and sanitized. Work in a clean environment to prevent contamination, and store fermenting mixtures away from direct sunlight and at appropriate temperatures (usually room temperature, around 68-75°F or 20-24°C).

While homemade enzyme production is generally safe, it's important to monitor your ferments for signs of harmful contamination, such as unusual colors, off-putting smells, or visible mold (apart from the white yeast film that often develops naturally). When in doubt, discard the batch and start fresh rather than risking consumption of potentially harmful substances.

Method 1: Fruit Enzyme Production

One of the simplest ways to create enzymes at home is through fruit fermentation. This method harnesses the natural enzymes present in fruits and enhances them through a controlled fermentation process. The resulting liquid is rich in beneficial enzymes and can be used for cleaning, as a probiotic drink when diluted, or as a natural fertilizer.

Citrus Enzyme Cleaner Recipe

A popular starting point is making citrus enzyme cleaner, which utilizes the natural cleaning properties of citrus peels. Begin by collecting peels from oranges, lemons, or grapefruits—about 3 cups worth. Chop them into smaller pieces to increase surface area. In a large glass jar, combine the peels with 1 cup of brown sugar and 10 cups of filtered water. The sugar feeds the fermentation process, while the water creates the medium for enzyme extraction.

Stir the mixture thoroughly with a wooden spoon until the sugar dissolves. Seal the jar loosely to allow gases to escape during fermentation, or use an airlock if available. Store in a cool, dark place and shake gently daily for the first week. After three months of fermentation, strain out the solids using cheesecloth and transfer the liquid to spray bottles. This enzyme cleaner works effectively on grease, bathroom surfaces, and even as a laundry booster when diluted properly.

Pineapple Enzyme Extract

Pineapple contains bromelain, a powerful enzyme with meat-tenderizing properties and potential health benefits. To extract it, collect the core and peel of a fresh pineapple—parts typically discarded but rich in enzymes. Chop these into small pieces and place in a blender with 2 cups of filtered water. Blend until smooth, then strain through cheesecloth into a glass jar.

Add 2 tablespoons of brown sugar and stir until dissolved. Cover with a coffee filter or cloth secured with a rubber band to allow airflow while keeping contaminants out. Let this mixture ferment at room temperature for 5-7 days, stirring daily. The resulting liquid can be strained again and refrigerated for up to two weeks. Use it as a meat tenderizer, digestive aid (diluted with water), or facial exfoliant.

Method 2: Enzyme Production Through Fermentation

Fermentation is a natural process where microorganisms like bacteria and yeast convert carbohydrates into alcohols, acids, and gases. This process naturally produces various enzymes as the microorganisms break down complex molecules. By controlling fermentation conditions, you can create enzyme-rich preparations with diverse applications.

Vegetable Enzyme Fermentation

This method creates a versatile enzyme preparation using vegetable scraps. Collect about 4 cups of vegetable scraps—carrot tops, cabbage cores, celery ends, onion skins, and similar kitchen waste work well. Chop these into small pieces and place them in a large glass jar. Add 1 cup of brown sugar or molasses and 10 cups of filtered water.

Stir thoroughly to dissolve the sugar, then cover with a breathable cloth secured with a rubber band. Store in a cool, dark place and stir daily for the first week. The mixture will bubble as fermentation progresses—this is normal and indicates that beneficial microorganisms are active. After about three months, strain the liquid through cheesecloth and store in sealed bottles. This enzyme preparation can be used as a natural fertilizer (diluted 1:500 with water), as a probiotic drink (highly diluted and in small quantities), or as a cleaning agent.

Koji Enzyme Cultivation

For those interested in more advanced enzyme production, koji cultivation offers an intriguing option. Koji is a culture of Aspergillus oryzae mold grown on grains, traditionally used in Japanese cuisine to make miso, sake, and soy sauce. The mold produces amylase and protease enzymes that break down starches and proteins.

To cultivate koji, start with koji spores (available from fermentation supply stores) and steamed rice. Spread the cooled steamed rice on a clean tray, sprinkle with koji spores according to package directions, and cover with a damp cloth. Maintain a warm temperature (85-95°F or 29-35°C) and high humidity for 48 hours. The rice will develop a white, fuzzy appearance as the koji mold grows. This koji can then be used to make amazake (a sweet rice drink), rice vinegar, or as a starter for other fermentation projects.

Storing and Using Your Homemade Enzymes

Proper storage is crucial for maintaining enzyme activity and preventing contamination. Most liquid enzyme preparations should be stored in glass bottles with tight-fitting lids, away from direct sunlight and heat sources. Refrigeration extends the shelf life of many enzyme preparations, though some, like citrus enzyme cleaners, remain stable at room temperature.

Shelf Life and Preservation

The shelf life of homemade enzymes varies depending on the preparation method and storage conditions. Fruit enzyme cleaners typically remain effective for 6-12 months when stored properly. Pineapple enzyme extract should be used within 2-3 weeks if refrigerated. Vegetable enzyme ferments can last 6-8 months in cool, dark conditions.

To extend shelf life, consider freezing portions of your enzyme preparations in ice cube trays, then transferring the frozen cubes to freezer bags. This method preserves enzyme activity and provides convenient portions for future use. Always label your enzyme preparations with the date of production and contents to track freshness.

Practical Applications

Homemade enzymes have numerous practical applications around the home. Fruit enzyme cleaners effectively cut through grease, remove soap scum, and clean glass surfaces without harsh chemicals. Diluted enzyme preparations make excellent plant fertilizers, providing nutrients and beneficial microorganisms to garden soil. Pineapple and papaya enzyme extracts can tenderize tough cuts of meat when applied as a marinade for 30-60 minutes before cooking.

For personal care, highly diluted fruit enzymes can be used as facial toners or added to bathwater for skin benefits. Some fermented enzyme preparations, when properly diluted, serve as probiotic supplements that may support digestive health—though it's advisable to consult with a healthcare provider before consuming homemade ferments for health purposes.

Troubleshooting Common Issues

Even with careful preparation, enzyme production sometimes encounters challenges. Understanding common issues and their solutions helps ensure successful outcomes and prevents wasted ingredients and effort.

Mold and Contamination

If you notice colored mold (green, black, or blue) on your ferment, this indicates contamination. Unlike the white yeast film that commonly forms on ferments, colored mold is a sign to discard the batch and start fresh. To prevent contamination, ensure all equipment is thoroughly cleaned, use chlorine-free water, and maintain appropriate fermentation conditions.

Foul odors beyond the normal tangy smell of fermentation also suggest contamination. Healthy ferments should smell acidic or vinegary, not putrid or rotten. If your preparation develops an unpleasant odor, it's safer to discard it and review your sanitation practices before starting again.

Slow or Stalled Fermentation

If your enzyme preparation shows little activity (minimal bubbling or change in appearance), temperature might be the culprit. Most fermentations work best between 68-75°F (20-24°C). Too cold, and microbial activity slows; too warm, and unwanted organisms might thrive. Moving your ferment to a location with more appropriate temperature can often restart the process.

Another common cause of stalled fermentation is insufficient sugar or nutrients for the microorganisms. If fermentation seems sluggish after the first week, try adding a tablespoon of additional sugar dissolved in a small amount of water. This often provides the needed food source to reinvigorate the process and continue enzyme production.

With these fundamentals in hand, you're well-equipped to begin your enzyme-making journey. Start with simple preparations like citrus enzyme cleaners, then progress to more complex projects as you gain confidence and experience. The world of enzyme production offers endless opportunities for exploration, combining ancient wisdom with modern understanding of biochemistry to create useful, sustainable products for everyday life.