The Ultimate Guide to Powder Enzymes: Benefits, Uses, and Applications

The Ultimate Guide to Powder Enzymes: Benefits, Uses, and Applications

Enzymes are the unsung heroes of countless industrial processes and everyday products we use. These remarkable biological catalysts have revolutionized industries ranging from food production to detergent manufacturing, offering sustainable alternatives to harsh chemicals while improving efficiency and product quality. Among the various forms enzymes come in, powder enzymes stand out for their stability, versatility, and ease of handling. This comprehensive guide explores everything you need to know about powder enzymes, from their fundamental nature to their diverse applications across multiple sectors.

Understanding Powder Enzymes

Powder enzymes are concentrated enzymatic formulations that have been carefully processed into a dry, granular form. Unlike their liquid counterparts, powder enzymes offer extended shelf life, reduced transportation costs, and greater stability across varying environmental conditions. The drying process typically involves techniques such as spray drying, freeze drying, or granulation, each preserving the catalytic activity of the enzymes while transforming them into a convenient powder format.

These biological catalysts work by lowering the activation energy required for chemical reactions, enabling processes to occur more rapidly and efficiently without being consumed in the reaction. What makes enzymes particularly valuable is their specificity – each enzyme targets particular substrates and catalyzes specific reactions, allowing for precise control in various applications.

Types of Common Powder Enzymes

The world of powder enzymes is diverse, with each type offering unique capabilities for different applications. Proteases break down proteins into smaller peptides and amino acids, making them invaluable in detergents for removing protein-based stains like blood and egg. Amylases target starches, converting them into simpler sugars – a property extensively utilized in baking, brewing, and textile processing. Lipases, meanwhile, specialize in breaking down fats and oils, finding applications in detergents, dairy processing, and biodiesel production.

Other significant powder enzymes include cellulases (which break down cellulose in plant cell walls), pectinases (which degrade pectin in plant tissues), and lactases (which hydrolyze lactose into glucose and galactose). Each of these enzymes serves specific industrial needs, from fabric softening to juice clarification to producing lactose-free dairy products.

Advantages of Powder Form

The powder format offers several distinct advantages over liquid enzyme preparations. First and foremost is stability – removing water significantly reduces the risk of microbial contamination and slows down the natural degradation process that enzymes undergo. This translates to longer shelf life, often extending from months to years. Additionally, powder enzymes are more concentrated, requiring less storage space and reducing shipping costs compared to their liquid counterparts.

Powder enzymes also offer greater formulation flexibility. They can be easily blended with other dry ingredients without concerns about ingredient compatibility or solution stability. This makes them particularly valuable in products like laundry detergents, where multiple enzymes and other active ingredients need to coexist in a stable formulation. For manufacturers, this means simplified handling, storage, and integration into existing production processes.

Industrial Applications

The versatility of powder enzymes has led to their adoption across numerous industries, where they drive efficiency, sustainability, and product innovation. From cleaning products to food processing, these biological catalysts have become essential components in modern manufacturing processes.

Cleaning and Detergent Industry

Perhaps the most recognizable application of powder enzymes is in laundry detergents and cleaning products. Modern detergent formulations typically contain a cocktail of enzymes – proteases to tackle protein stains, amylases for starch-based soils, lipases for greasy marks, and cellulases to restore fabric appearance and softness. These enzymes enable effective cleaning at lower temperatures, reducing energy consumption while delivering superior stain removal.

The benefits extend beyond performance. Enzyme-powered detergents allow for reduced use of harsh chemicals like phosphates, contributing to more environmentally friendly products. Major detergent manufacturers like Procter & Gamble and Unilever have embraced enzyme technology, highlighting the "biological" cleaning power in their marketing while continuously refining their enzyme blends to tackle increasingly specific cleaning challenges.

Beyond laundry, powder enzymes have found their way into dishwashing detergents, where they break down food residues, and specialized cleaning products for industries ranging from healthcare to food processing, where they help dissolve biofilms and organic contaminants.

Food and Beverage Processing

The food industry relies heavily on powder enzymes to improve production processes and enhance product quality. In baking, amylases modify flour starches to provide consistent dough properties and improve bread volume and texture. Proteases adjust gluten strength, while xylanases enhance dough handling and final product quality. These enzymes allow bakers to achieve consistent results despite variations in flour quality.

Dairy processing represents another major application area. Rennet (containing the enzyme chymosin) has been used for centuries in cheese production to coagulate milk proteins. Modern cheese production often uses microbial-derived chymosin in powder form. Lactase enzymes enable the production of lactose-free milk products, opening the dairy market to lactose-intolerant consumers.

In beverage production, enzymes clarify fruit juices by breaking down pectins that cause cloudiness. The brewing industry employs amylases to convert grain starches into fermentable sugars, while proteases reduce chill haze in beer. Wine producers use pectinases to improve juice extraction and clarification, enhancing both production efficiency and final product quality.

Pharmaceutical and Biotechnology Applications

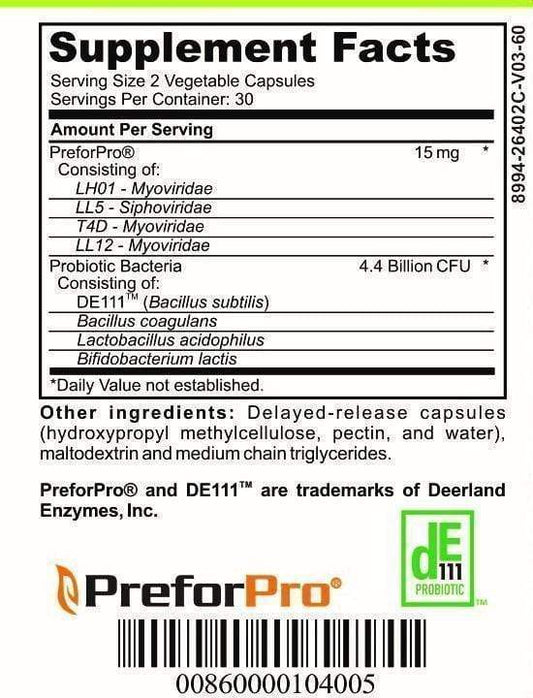

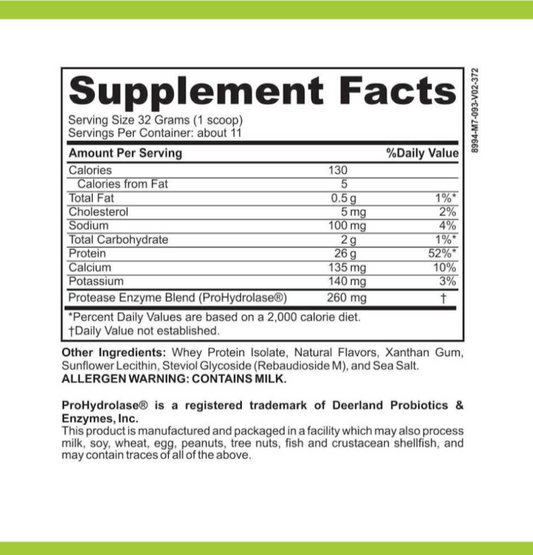

The pharmaceutical industry leverages powder enzymes for both therapeutic applications and manufacturing processes. digestive enzymes are formulated into supplements to aid digestion for individuals with enzyme deficiencies. Specialized enzymes like lactase are used to create lactose-free products for those with lactose intolerance, while others like bromelain from pineapple are utilized for their anti-inflammatory properties.

In drug manufacturing, enzymes enable more precise and environmentally friendly synthesis routes compared to traditional chemical methods. Their specificity allows for the creation of pure stereoisomers and complex molecules that would be difficult to produce through conventional chemistry. Immobilized enzyme systems, where powder enzymes are attached to solid supports, enable continuous manufacturing processes with reusable enzyme catalysts.

Emerging Applications and Innovations

The field of enzyme technology continues to evolve, with researchers and companies exploring new applications and enhancing existing enzyme performance through various techniques. These innovations are expanding the potential of powder enzymes across industries.

Biofuel Production

As the world seeks sustainable alternatives to fossil fuels, enzymes are playing a crucial role in biofuel production. Cellulases and hemicellulases break down plant biomass into fermentable sugars, which can then be converted into bioethanol. Companies like Novozymes and DuPont have developed specialized enzyme cocktails that efficiently convert agricultural residues, wood chips, and dedicated energy crops into biofuel feedstocks.

The advantage of enzymatic processes over chemical alternatives is their specificity and milder reaction conditions, which reduce energy requirements and minimize the production of undesirable byproducts. Ongoing research focuses on discovering and engineering enzymes with greater stability at high temperatures and resistance to inhibitors present in biomass, further improving the economic viability of biofuel production.

Textile Processing

The textile industry has embraced powder enzymes as eco-friendly alternatives to harsh chemicals traditionally used in fabric processing. Amylases remove starch-based sizing agents applied during weaving, while cellulases create the stonewashed effect in denim without actual stones, reducing water usage and fabric damage. Catalases decompose excess hydrogen peroxide after bleaching, eliminating the need for additional chemical reducing agents.

These enzymatic processes not only reduce environmental impact but also improve fabric quality and process efficiency. The precision of enzyme action prevents fiber damage that can occur with more aggressive chemical treatments, resulting in softer fabrics with better durability. As sustainability becomes increasingly important in textile manufacturing, enzyme-based processes represent a significant step toward greener production methods.

Handling and Storage Best Practices

To maintain the activity and effectiveness of powder enzymes, proper handling and storage are essential. These biological catalysts, while stable in powder form, can still be affected by environmental factors that accelerate denaturation and activity loss.

Temperature and Humidity Control

Most powder enzymes should be stored in cool, dry conditions to maximize shelf life. Elevated temperatures accelerate protein denaturation, while moisture can trigger premature enzyme activation or promote microbial growth. The specific temperature requirements vary by enzyme type, but generally, storage below 25°C (77°F) is recommended, with some enzymes benefiting from refrigeration at 2-8°C (36-46°F).

Humidity control is equally important. Many powder enzymes are hygroscopic, meaning they readily absorb moisture from the air. Once opened, containers should be tightly resealed, and in high-humidity environments, desiccants may be necessary to maintain dryness. Some manufacturers provide specialized packaging with moisture barriers or individual sachets to protect enzyme activity until the point of use.

Safety Considerations

While enzymes are natural proteins, they require proper handling to ensure worker safety. Fine enzyme powders can become airborne during handling, potentially causing respiratory sensitization or allergic reactions in some individuals. To mitigate these risks, handling should occur in well-ventilated areas, preferably with local exhaust ventilation, and personal protective equipment including dust masks, gloves, and eye protection should be used.

Many modern enzyme formulations address these concerns through granulation or encapsulation technologies that reduce dustiness while maintaining dissolution properties. These dust-free or low-dust formulations significantly improve handling safety while preserving enzyme functionality in the final application.

The Future of Powder Enzymes

The powder enzyme market continues to expand, driven by increasing demand for sustainable processing technologies and growing applications across industries. Several trends are shaping the future of this dynamic field, from enhanced enzyme engineering to novel delivery systems.

Protein engineering and directed evolution techniques are enabling the development of enzymes with improved stability, activity, and specificity. These enhanced enzymes can function under more extreme conditions – higher temperatures, broader pH ranges, and in the presence of inhibitors or denaturants – expanding their potential applications. Computational tools are accelerating this process, allowing researchers to predict beneficial mutations and design enzymes for specific reactions.

Sustainability remains a powerful driver for enzyme adoption. As industries face pressure to reduce their environmental footprint, enzymes offer a path to greener processes with lower energy requirements, reduced water usage, and decreased chemical consumption. This alignment with sustainability goals ensures continued investment in enzyme technology across sectors.

As our understanding of enzyme science deepens and manufacturing technologies advance, powder enzymes will undoubtedly continue to transform industries, enabling more efficient, sustainable, and innovative processes and products. Whether breaking down stains in your laundry or converting biomass into renewable fuels, these remarkable biological catalysts have firmly established themselves as essential tools in our technological toolkit.