Is Nisin Preparation High In Histamine

Is Nisin Preparation High In Histamine

Nisin preparation has gained attention due to its role in food preservation. However, concerns have been raised regarding its potential for containing high levels of histamine. In this article, we will explore the relationship between nisin and histamine, the implications for consumers and manufacturers, and strategies for mitigating histamine levels in nisin preparation.

Understanding Nisin: An Overview

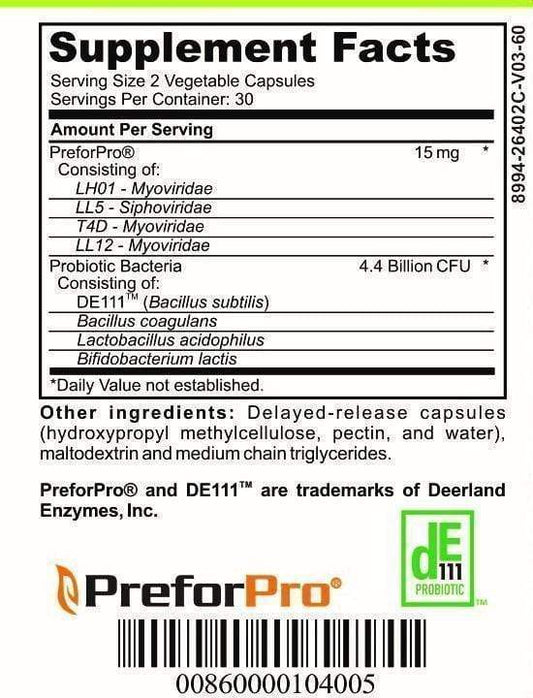

Nisin is a natural antimicrobial peptide produced by certain strains of Lactococcus lactis. It has been widely used in the food industry as a preservative, particularly in dairy products and canned foods. Nisin works by inhibiting the growth of spoilage and pathogenic bacteria, thus extending the shelf life of perishable foods.

Nisin's effectiveness in food preservation is due to its unique mechanism of action. When nisin comes into contact with bacterial cell membranes, it disrupts their integrity by forming pores. These pores destabilize the membrane, leading to leakage of cellular contents and ultimately cell death. This targeted approach makes nisin an important tool in the battle against foodborne pathogens.

The Role of Nisin in Food Preservation

Food preservation is crucial for maintaining the quality and safety of food products. Without proper preservation methods, food can spoil quickly, leading to economic losses and potential health risks. Nisin offers a natural and effective means of preventing microbial spoilage and reducing the risk of foodborne illnesses.

One of the key advantages of using nisin as a preservative is its broad spectrum of activity. It has been shown to be effective against a wide range of bacteria, including both Gram-positive and Gram-negative species. This versatility makes it a valuable tool for preserving various food products.

In addition to its antimicrobial properties, nisin also has other benefits in food preservation. It has been found to enhance the flavor and texture of certain foods, making them more appealing to consumers. Furthermore, nisin has been shown to inhibit the production of certain toxins by bacteria, further reducing the risk of foodborne illnesses.

The Production Process of Nisin

The production process of nisin involves fermentation of Lactococcus lactis strains in a controlled environment. These bacteria are carefully selected for their ability to produce high levels of nisin. The fermentation process provides the bacteria with the necessary conditions to grow and produce the antimicrobial peptide.

Once the bacteria have produced nisin, it is extracted and purified for use in food applications. The extraction process typically involves separating the nisin from the bacterial cells and other impurities. This ensures that the final product is pure and free from any potential contaminants.

The purified nisin is then formulated into various forms suitable for different food applications. It can be added directly to food products or incorporated into packaging materials to provide continuous protection against microbial growth. The careful production process ensures the quality and safety of nisin products, making them suitable for use in a wide range of food products.

Histamine: A Closer Look

Histamine is a naturally occurring compound involved in various physiological processes in the human body. It acts as a chemical messenger and plays a role in regulating the immune response, gastric acid secretion, and neurotransmission. While histamine is essential for normal bodily functions, high levels can have detrimental effects.

The Biological Role of Histamine

Histamine acts as a signaling molecule in the immune system, helping to regulate allergic and inflammatory responses. It is released by immune cells in response to allergens or pathogens, triggering symptoms such as itching, swelling, and redness. Additionally, histamine plays a role in the regulation of sleep-wake cycles and the control of gastric acid secretion.

When histamine is released during an allergic reaction, it binds to specific receptors on nearby cells, causing them to become activated. This activation leads to the release of other molecules that contribute to the inflammatory response, such as cytokines and chemokines. These molecules attract immune cells to the site of the reaction, amplifying the immune response and promoting the clearance of the allergen or pathogen.

Furthermore, histamine is involved in the regulation of sleep-wake cycles. It is released in higher amounts during wakefulness and lower amounts during sleep. This suggests that histamine plays a role in promoting wakefulness and maintaining alertness. Conversely, medications that block histamine receptors, such as antihistamines, can cause drowsiness as a side effect.

Sources of Histamine in Food

Histamine can be found naturally in certain foods or can be formed through the microbial activity of bacteria on protein-rich foods. Consuming foods with high levels of histamine can lead to histamine intolerance or allergic reactions in susceptible individuals. Common food sources of histamine include aged cheeses, fermented foods, cured meats, and certain fish species.

Aged cheeses, such as blue cheese and Parmesan, have higher levels of histamine due to the aging process. The longer the cheese is aged, the higher the histamine content. Fermented foods, such as sauerkraut and kimchi, also contain histamine as a byproduct of the fermentation process. Cured meats, such as salami and bacon, can have elevated levels of histamine due to the curing process, which involves the breakdown of proteins. Certain fish species, such as tuna, mackerel, and sardines, naturally contain high levels of histamine, which can increase further if the fish is not stored properly.

It is important for individuals with histamine intolerance or allergies to be aware of these food sources and to avoid consuming them to prevent adverse reactions. Symptoms of histamine intolerance can include headaches, flushing, hives, digestive issues, and respiratory problems. If you suspect histamine intolerance, it is recommended to consult with a healthcare professional for proper diagnosis and guidance on managing your diet.

The Connection Between Nisin and Histamine

Given the potential presence of histamine in certain foods, concerns have been raised about the connection between nisin and histamine levels in nisin preparation. However, it is important to understand that the production process of nisin does not typically involve histamine-producing bacteria. Therefore, nisin itself is unlikely to contain substantial amounts of histamine.

The Potential for Histamine in Nisin Preparation

While nisin production may not directly contribute to histamine levels, the potential for histamine contamination can arise during the handling and processing of nisin products. Cross-contamination with histamine-producing bacteria or exposure to histamine-rich environments can lead to trace amounts of histamine in nisin preparations.

Factors Influencing Histamine Levels in Nisin

Several factors can influence the histamine levels in nisin preparations. The quality of raw materials, processing conditions, and storage practices all play a role in determining the final histamine content. Strict adherence to Good Manufacturing Practices (GMP) and quality control measures can help minimize the risk of histamine contamination during nisin production.

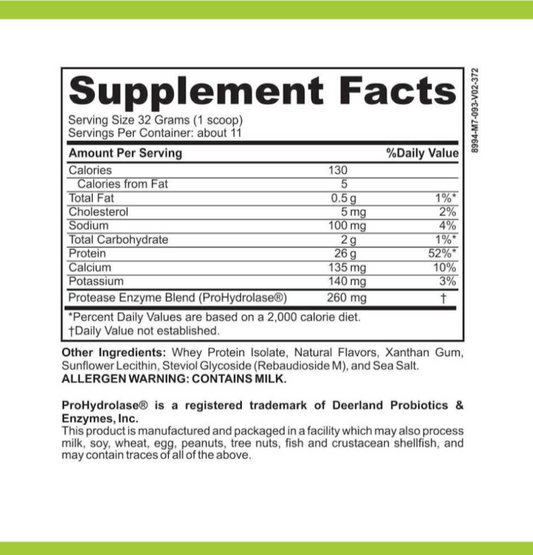

One of the key factors that can affect histamine levels in nisin is the quality of raw materials used in the production process. The source of the raw materials, such as milk or whey, can impact the presence of histamine-producing bacteria. Therefore, it is crucial for manufacturers to carefully select their suppliers and ensure that the raw materials are of high quality and free from contamination.

In addition to the raw materials, processing conditions also play a significant role in histamine levels. The temperature and pH during the production process can influence the growth of histamine-producing bacteria. By maintaining optimal conditions, manufacturers can minimize the risk of histamine formation and contamination in nisin preparations.

Furthermore, storage practices can impact the histamine levels in nisin. Improper storage conditions, such as exposure to high temperatures or prolonged storage periods, can promote the growth of histamine-producing bacteria and lead to higher histamine content in the final product. Therefore, it is essential for manufacturers and distributors to handle and store nisin products in accordance with recommended guidelines to ensure the quality and safety of the product.

Overall, while nisin itself is unlikely to contain substantial amounts of histamine, it is important to consider the potential for histamine contamination during the handling, processing, and storage of nisin preparations. By implementing strict quality control measures and adhering to GMP, manufacturers can minimize the risk of histamine presence and ensure the safety of nisin products.

Implications for Consumers and Manufacturers

The potential presence of histamine in nisin preparations raises important implications for both consumers and manufacturers. It is essential for consumers to be aware of the possibility of histamine contamination and exercise caution, especially if they have histamine intolerance or allergies. For manufacturers, stringent quality control measures and regular testing of nisin products can help ensure the safety and purity of their offerings.

When it comes to consumer implications, understanding the health risks associated with high histamine levels is crucial. Consuming foods or food products with high levels of histamine can lead to adverse health effects, particularly in individuals with histamine intolerance or allergies. Symptoms of histamine toxicity include headaches, flushing, digestive issues, and in severe cases, anaphylactic shock. Recognizing and avoiding histamine-rich foods is crucial for managing these health risks.

Manufacturers, on the other hand, face regulatory considerations when it comes to nisin and histamine. The regulatory landscape surrounding nisin and histamine varies across different jurisdictions. Regulatory authorities set limits on histamine levels in food products to ensure consumer safety. Manufacturers must adhere to these regulations and implement measures to monitor and control histamine levels in their nisin preparations.

Ensuring the safety and purity of nisin products requires manufacturers to implement stringent quality control measures. Regular testing of nisin products is essential to detect any potential histamine contamination. This involves conducting thorough laboratory analysis and adhering to established protocols to ensure accurate and reliable results.

Furthermore, manufacturers must also consider the source of their nisin. The quality and purity of the raw materials used in nisin production play a crucial role in minimizing the risk of histamine contamination. Sourcing nisin from reputable suppliers who prioritize quality control and follow strict manufacturing processes can help mitigate the potential presence of histamine in the final product.

Additionally, manufacturers should invest in research and development to explore innovative methods for histamine detection and prevention. This includes staying up-to-date with advancements in technology and scientific knowledge to continuously improve the safety and quality of nisin products. Collaboration with experts in the field can also provide valuable insights and guidance in managing histamine-related challenges.

Ultimately, both consumers and manufacturers play important roles in ensuring the safety and purity of nisin products. By being informed about the potential risks of histamine contamination, consumers can make educated choices and take necessary precautions. Manufacturers, on the other hand, must prioritize quality control, regular testing, and adherence to regulatory requirements to provide consumers with safe and reliable nisin products.

Mitigating Histamine Levels in Nisin Preparation

Efforts to reduce histamine levels in nisin preparation are essential for ensuring product safety and meeting regulatory requirements. Manufacturers are continuously exploring strategies and techniques to mitigate histamine contamination during nisin production.

Current Strategies and Techniques

Manufacturers employ various methods to minimize histamine contamination during nisin production, including strict quality control, proper sanitation practices, and regular testing for histamine levels. Additionally, implementing Hazard Analysis and Critical Control Points (HACCP) systems can help identify and prevent potential sources of histamine contamination.

Future Research Directions

As scientific understanding of histamine production and contamination improves, ongoing research is focused on developing innovative approaches to further reduce histamine levels in nisin preparation. Novel techniques such as advanced microbial detection methods and targeted interventions hold promise for a more preventive and efficient control of histamine contamination.

In conclusion, while the potential for histamine in nisin preparation should be acknowledged, stringent quality control measures can effectively mitigate histamine levels. By staying informed about histamine-rich foods and implementing proper handling and processing practices, manufacturers can ensure the safety and quality of nisin products, providing consumers with effective food preservation options without significant histamine contamination.