Fructan Enzymes: Functions, Types, and Applications in Biotechnology

Fructan Enzymes: Functions, Types, and Applications in Biotechnology

Fructans represent a diverse group of fructose polymers found in numerous plants, serving as energy storage molecules similar to starch. The enzymes that interact with these compounds—fructan enzymes—have garnered significant attention in recent years due to their remarkable versatility and applications across multiple industries. From food processing to medical treatments and biofuel production, these specialized proteins are revolutionizing biotechnological approaches to some of our most pressing challenges.

Understanding fructan enzymes isn't just academically interesting—it has practical implications for anyone interested in biotechnology, nutrition science, or even managing digestive health conditions like IBS. This comprehensive guide explores the fascinating world of fructan enzymes, their biological functions, diverse types, and the expanding landscape of their applications.

Understanding Fructans and Their Significance

Fructans are carbohydrates composed of fructose units linked together in various configurations. Unlike simple sugars that are readily digested, fructans pass through the human small intestine largely intact, eventually reaching the colon where gut bacteria ferment them. This property classifies fructans as prebiotics—compounds that selectively stimulate the growth of beneficial gut bacteria.

Common dietary sources of fructans include wheat, onions, garlic, chicory root, and Jerusalem artichokes. While beneficial for many people, fructans can trigger digestive symptoms in individuals with irritable bowel syndrome (IBS) or those following low-FODMAP diets. This is where fructan enzymes become particularly relevant, as they can break down these complex carbohydrates into more digestible forms.

The Chemical Structure of Fructans

Fructans exist in several structural forms, with inulin and levan being the most common. Inulin consists of fructose units linked by β(2→1) bonds, while levan features β(2→6) linkages. These structural differences influence how fructan enzymes interact with the substrates and determine the specific enzyme required for their breakdown. The degree of polymerization (DP)—the number of fructose units in the chain—also varies widely, from just a few units to several hundred, creating additional complexity for enzymatic processing.

Biological Roles of Fructans in Plants

In the plant world, fructans serve multiple critical functions. Primarily, they act as carbohydrate reserves, storing energy when photosynthesis exceeds immediate needs. Additionally, fructans help plants survive environmental stresses like drought and freezing temperatures by stabilizing cell membranes and preventing ice crystal formation in tissues. Some evidence suggests fructans may also play roles in osmotic regulation and protection against oxidative stress, highlighting their multifunctional nature in plant physiology.

Key Types of Fructan Enzymes

Fructan enzymes fall into two primary categories: those involved in fructan synthesis and those responsible for fructan degradation. Each category contains several specific enzymes with unique properties and functions. Understanding these distinctions is crucial for applications in both research and industry.

Fructan Synthesis Enzymes

The creation of fructans in plants relies primarily on two key enzymes: sucrose:sucrose 1-fructosyltransferase (1-SST) and fructan:fructan 1-fructosyltransferase (1-FFT). The 1-SST enzyme initiates fructan synthesis by transferring a fructose unit from one sucrose molecule to another, creating a trisaccharide called 1-kestose. Subsequently, 1-FFT extends the fructan chain by transferring fructose units between fructan molecules of different lengths.

For levan-type fructan synthesis, plants utilize sucrose:fructan 6-fructosyltransferase (6-SFT), which creates β(2→6) linkages instead. The coordinated action of these enzymes determines the final structure and length of the fructan polymers, which vary significantly between plant species and even between different tissues within the same plant.

Fructan Degradation Enzymes

When plants need to mobilize their fructan reserves, they employ fructan exohydrolases (FEHs), which cleave terminal fructose units from the fructan chain. Different types of FEHs exist, including 1-FEH and 6-FEH, which specifically hydrolyze β(2→1) and β(2→6) linkages, respectively. These enzymes play crucial roles during periods of energy demand, such as regrowth after dormancy or during seed development.

Microbial systems produce inulinases and levanases that break down fructans more completely. Endo-inulinases cleave internal bonds in the fructan chain, while exo-inulinases work from the non-reducing end. These microbial enzymes have become particularly valuable in industrial applications due to their efficiency and stability under various processing conditions.

Enzyme Structure and Mechanism

Most fructan enzymes belong to glycoside hydrolase family 32 (GH32) or family 68 (GH68), sharing similar three-dimensional structures despite differences in their specific activities. They typically feature a β-propeller domain containing the catalytic site, sometimes accompanied by additional domains that influence substrate binding or enzyme stability. The catalytic mechanism generally involves an acid/base reaction, where specific amino acid residues in the active site facilitate the breaking or formation of glycosidic bonds between fructose units.

Industrial and Biotechnological Applications

The unique properties of fructan enzymes have made them valuable tools across multiple industries. Their ability to modify complex carbohydrates in specific ways enables applications ranging from food production to pharmaceutical development and beyond.

Food and Beverage Industry

In food processing, fructan enzymes are extensively used to produce fructose syrups and fructooligosaccharides (FOS), which serve as alternative sweeteners and prebiotic ingredients. Inulinases convert inulin from chicory or Jerusalem artichoke into FOS with varying chain lengths, creating products with different sweetness profiles and prebiotic potencies. These enzyme-derived ingredients appear in numerous products, from dairy alternatives to baked goods and beverages.

Fructan enzymes also play a role in brewing, where they help improve fermentation efficiency by breaking down complex carbohydrates that brewing yeasts cannot naturally process. This application results in lower-calorie beers with improved flavor profiles. Similarly, in wine production, these enzymes can enhance juice extraction and clarification processes.

Health and Pharmaceutical Applications

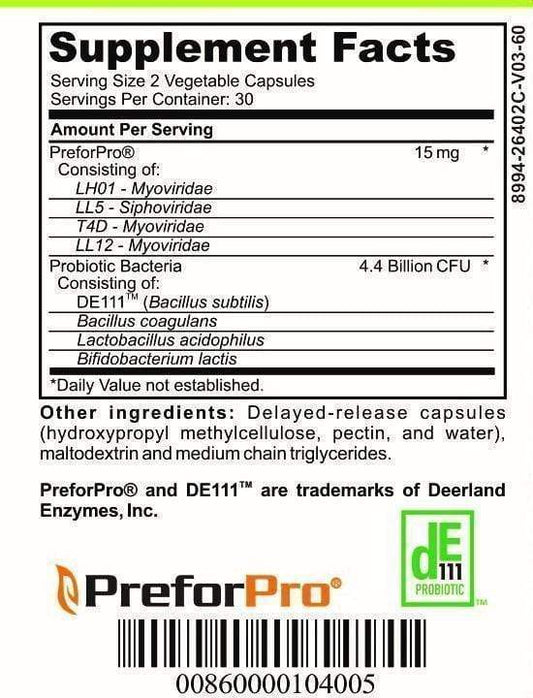

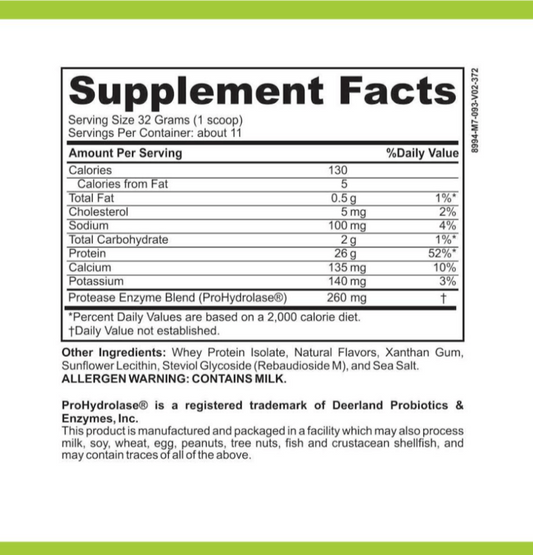

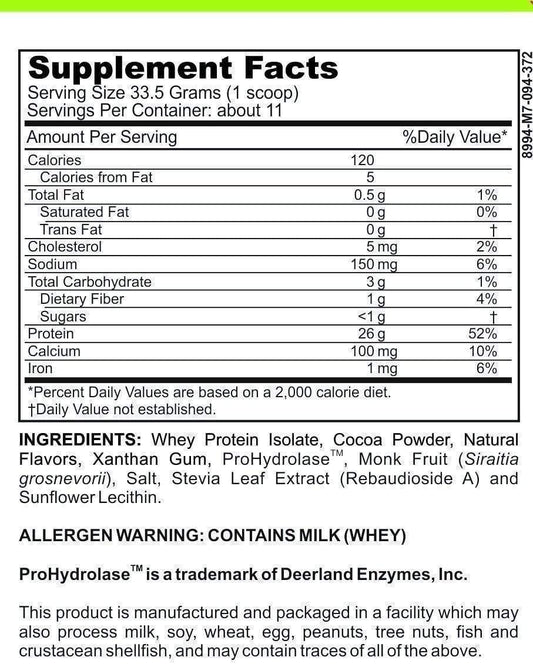

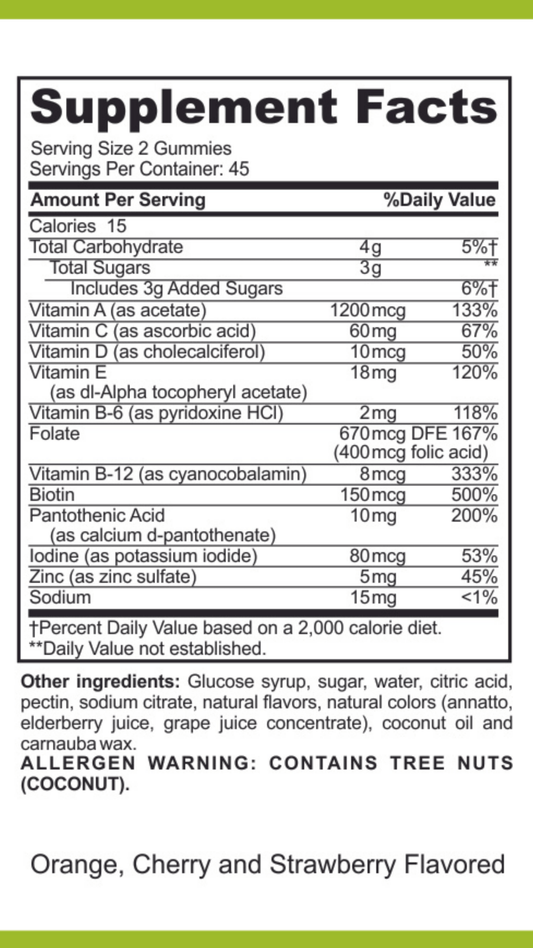

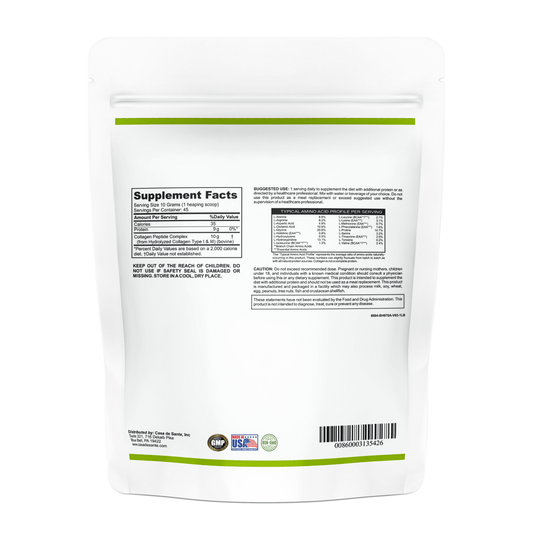

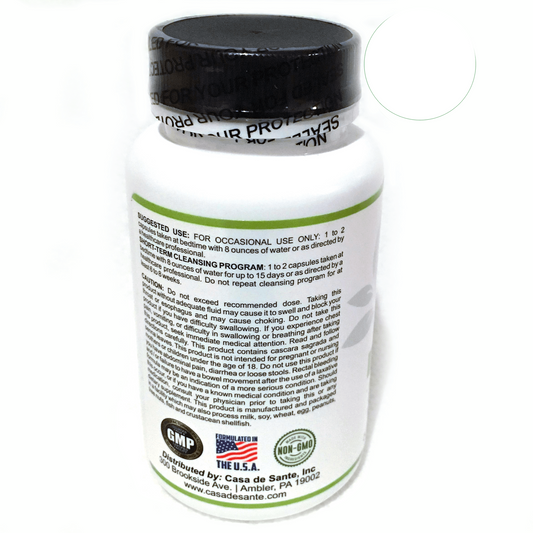

Perhaps one of the most promising areas for fructan enzymes lies in digestive health applications. For individuals with fructan sensitivity or those following low-FODMAP diets, supplemental fructan enzymes can help break down problematic fructans before they reach the colon, potentially reducing digestive symptoms. Products like Casa de Sante's digestive enzyme supplements incorporate specific enzymes that target fructans and other FODMAPs, offering relief for those with sensitive digestive systems while allowing them to enjoy a wider variety of foods.

Beyond digestive applications, fructan-derived compounds show promise in pharmaceutical development. FOS produced by fructan enzymes serve as prebiotics that selectively promote beneficial gut bacteria, potentially improving immune function and overall health. Research also explores using modified fructans as drug delivery systems or as components in wound healing materials, highlighting the versatility of these enzyme-processed compounds.

Biofuel and Industrial Applications

The bioethanol industry has embraced fructan enzymes as valuable tools for improving production efficiency. By converting fructan-rich plant materials like agave or Jerusalem artichoke into fermentable sugars, these enzymes help create sustainable biofuel feedstocks that don't compete with food crops. The process typically involves using microbial inulinases to hydrolyze fructans completely, followed by yeast fermentation to produce ethanol.

In other industrial contexts, fructan enzymes facilitate the production of platform chemicals like 5-hydroxymethylfurfural (HMF) and levulinic acid from fructose. These compounds serve as building blocks for various materials, including bioplastics and specialty chemicals, offering more sustainable alternatives to petroleum-derived products.

Practical Applications in Everyday Life

Beyond industrial settings, fructan enzymes have practical applications that impact everyday life, particularly for those managing specific dietary needs or health conditions.

Digestive Health Management

For individuals with IBS or FODMAP sensitivities, fructan enzymes represent a practical tool for managing symptoms while maintaining dietary flexibility. Supplemental enzymes, like those found in Casa de Sante's digestive enzyme formulations, can be taken before meals containing fructan-rich foods to help break down these challenging carbohydrates. When combined with probiotic and prebiotic supplements that support overall gut health, these enzyme products offer a comprehensive approach to digestive wellness.

Many people find that a combination approach—using both dietary strategies and enzyme supplements—provides the best results. Casa de Sante's personalized meal plans for low FODMAP diets incorporate this knowledge, suggesting appropriate enzyme supplementation alongside carefully designed recipes that minimize symptom triggers while maximizing nutritional value.

Fructan-Friendly Recipe: Enzyme-Assisted Garlic Infused Oil

Here's a practical application of fructan enzyme concepts in a kitchen-friendly format:

Enzyme-Assisted Garlic Infused Oil

Description: This infused oil captures the flavor of garlic without the fructans that can trigger digestive symptoms. The process leverages the principle behind how fructan enzymes work, though in this case, we're using a physical separation method rather than actual enzymes.

- 2 cups olive oil

- 8-10 garlic cloves, peeled and crushed

- 1 teaspoon dried herbs (optional: rosemary, thyme, or oregano)

- In a small saucepan, heat olive oil over low heat until warm but not smoking.

- Add crushed garlic cloves and optional herbs.

- Maintain low heat for 20 minutes, ensuring the oil never simmers or boils.

- Remove from heat and let cool for 30 minutes.

- Strain the oil through a fine-mesh sieve or cheesecloth into a sterilized glass bottle.

- Discard the solids (which contain the fructans).

- Store in a cool, dark place for up to 2 weeks, or refrigerate for longer storage.

Prep Time: 5 minutes

Cook Time: 20 minutes

Yield: 2 cups

Cuisine: Mediterranean

Category: Condiment

Future Directions and Research

The field of fructan enzyme research continues to evolve rapidly, with several promising directions emerging in recent years. Advances in protein engineering have enabled the development of enzymes with enhanced stability, specificity, or activity, expanding their potential applications. For example, researchers have created modified inulinases that function efficiently at higher temperatures or in the presence of organic solvents, making them more suitable for industrial processes.

Synthetic biology approaches are also being explored to create novel enzyme systems that can produce custom-designed fructan structures with specific properties. These engineered fructans could have applications in advanced materials, targeted drug delivery systems, or specialized food ingredients with precise health benefits.

As our understanding of the gut microbiome expands, the relationship between fructan enzymes, dietary fructans, and microbial communities presents another fascinating research avenue. Developing prebiotic formulations that combine specific fructan structures with complementary probiotics could lead to more effective approaches for managing gut health and addressing conditions ranging from IBS to metabolic disorders.

Emerging Technologies

New technologies are enhancing how we study and utilize fructan enzymes. High-throughput screening methods enable researchers to rapidly identify novel enzymes from diverse biological sources, including previously unexplored microorganisms from extreme environments. These newly discovered enzymes often possess unique properties that make them valuable for specialized applications.

Immobilization techniques that attach enzymes to solid supports are improving the efficiency and reusability of fructan enzymes in industrial processes. These approaches reduce production costs while minimizing environmental impact, making enzyme-based processes more economically viable and sustainable.

The integration of fructan enzyme technology with other emerging fields, such as 3D bioprinting or microfluidics, opens additional possibilities for creating advanced materials or diagnostic tools. As these technologies mature, we can expect to see increasingly sophisticated applications that leverage the specific carbohydrate-modifying capabilities of these remarkable enzymes.