Understanding Fructan Hydrolase Enzyme: Functions and Applications

Understanding Fructan Hydrolase Enzyme: Functions and Applications

Enzymes are the unsung heroes of biochemical processes, silently catalyzing reactions that sustain life and drive industrial processes. Among these remarkable biological catalysts, fructan hydrolase enzymes stand out for their specialized role in breaking down complex fructan molecules. These enzymes have garnered significant attention not only in the scientific community but also in various industries, from food processing to biofuel production. This article delves into the fascinating world of fructan hydrolase enzymes, exploring their structure, functions, and the myriad ways they're being harnessed in practical applications.

The Biochemistry of Fructan Hydrolase

Fructan hydrolase belongs to the glycoside hydrolase family of enzymes, specifically designed to break down fructans—polymers composed of fructose units linked by β-(2→1) or β-(2→6) glycosidic bonds. These enzymes catalyze the hydrolysis reaction, adding water to cleave these bonds and release individual fructose molecules or shorter fructan chains. The reaction is remarkably efficient, occurring at ambient temperatures and neutral pH, conditions that would otherwise require harsh chemicals or extreme heat to achieve similar results.

The enzyme's active site contains specific amino acid residues that position the fructan substrate and facilitate the hydrolysis reaction. This specificity is what makes fructan hydrolase so valuable—it can selectively target fructan molecules without affecting other carbohydrates present in the same environment. This selectivity is crucial for many industrial and medical applications where precision is paramount.

Types of Fructan Hydrolases

Fructan hydrolases come in several varieties, each with distinct substrate preferences and hydrolysis patterns. Inulinases primarily target inulin, a fructan with β-(2→1) linkages commonly found in plants like chicory and Jerusalem artichoke. Levanases, on the other hand, specialize in breaking down levan, a fructan with β-(2→6) bonds prevalent in certain bacterial species. Some fructan hydrolases exhibit exo-activity, cleaving fructose units from the non-reducing end of the polymer chain, while others display endo-activity, breaking internal bonds to produce shorter oligosaccharides.

This diversity in fructan hydrolases reflects the evolutionary adaptations of different organisms to utilize various fructan sources. Microorganisms like Aspergillus niger and Kluyveromyces marxianus produce robust fructan hydrolases that have become valuable tools in biotechnology. Plants also produce these enzymes, particularly during fruit ripening or when mobilizing stored carbohydrates during germination or regrowth after dormancy.

Molecular Structure and Mechanism

The three-dimensional structure of fructan hydrolases reveals a complex arrangement of protein domains that work in concert to achieve catalytic efficiency. Most fructan hydrolases adopt a β-propeller fold, with the active site nestled within a deep pocket that accommodates the fructan substrate. X-ray crystallography studies have illuminated the precise positioning of catalytic residues, typically including acidic amino acids that participate in the hydrolysis reaction through acid-base catalysis.

The catalytic mechanism involves a nucleophilic attack on the anomeric carbon of the glycosidic bond, followed by the formation of a covalent enzyme-substrate intermediate. This intermediate is subsequently hydrolyzed, releasing the cleaved fructose unit and regenerating the enzyme for another catalytic cycle. This elegant mechanism allows fructan hydrolases to process multiple substrate molecules rapidly, making them highly efficient biological catalysts.

Natural Roles in Plants and Microorganisms

In nature, fructan hydrolase enzymes serve crucial functions across various organisms. Plants utilize these enzymes to manage their carbohydrate reserves, particularly during periods of stress or developmental transitions. When a plant needs to mobilize stored energy, fructan hydrolases break down fructan reserves into fructose units that can enter metabolic pathways to generate ATP, the cell's energy currency.

Seasonal changes trigger fructan hydrolase activity in many perennial plants. During autumn, these plants accumulate fructans as storage compounds, and when spring arrives, fructan hydrolases activate to provide energy for new growth. This cycle is particularly important in temperate grasses and cereals, where fructans can constitute up to 70% of dry weight in some tissues.

Role in Plant Stress Response

Fructan metabolism, regulated by fructan hydrolases, plays a significant role in plant responses to environmental stresses. During drought conditions, the breakdown of fructans by hydrolase enzymes helps maintain osmotic balance and protects cellular structures from dehydration damage. Similarly, during cold stress, fructan hydrolysis contributes to freezing tolerance by providing soluble sugars that act as cryoprotectants for sensitive cellular membranes.

Research has shown that plants with enhanced fructan hydrolase activity often exhibit improved resilience to abiotic stresses. This knowledge has prompted efforts to engineer crops with modified fructan metabolism to enhance their stress tolerance, potentially addressing challenges posed by climate change and expanding agriculture into marginal lands.

Microbial Fructan Hydrolases

In the microbial world, fructan hydrolases serve as tools for nutrient acquisition. Soil bacteria and fungi produce these enzymes to access fructans present in plant debris or root exudates. Some beneficial rhizosphere microorganisms use fructan hydrolases to establish symbiotic relationships with plants, breaking down fructans to obtain carbon while providing plants with nutrients or protection against pathogens.

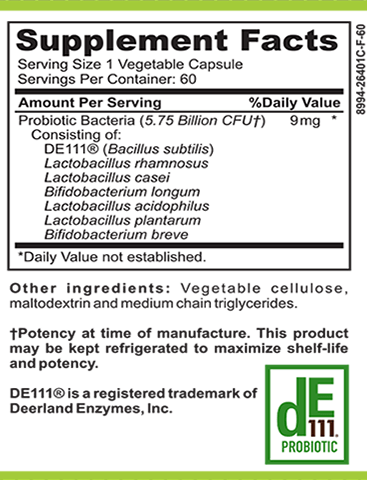

Interestingly, certain gut microbiota also produce fructan hydrolases to digest dietary fructans that humans cannot break down. This microbial activity in the colon generates short-chain fatty acids that benefit gut health, highlighting the interconnected nature of enzyme activities across different organisms in an ecosystem.

Industrial Applications

The unique properties of fructan hydrolase enzymes have made them valuable tools in various industries. Their ability to specifically target fructan molecules under mild conditions offers significant advantages over chemical processes, including reduced energy consumption, fewer byproducts, and greater product purity. As industries increasingly prioritize sustainable practices, enzymatic processes using fructan hydrolases are gaining prominence.

Commercial production of these enzymes typically involves microbial fermentation using optimized strains of fungi or bacteria. Companies like Novozymes and DuPont have developed efficient production systems that yield high-quality enzyme preparations suitable for industrial applications. These commercial enzymes undergo rigorous quality control to ensure consistent performance across different batches.

Food and Beverage Industry

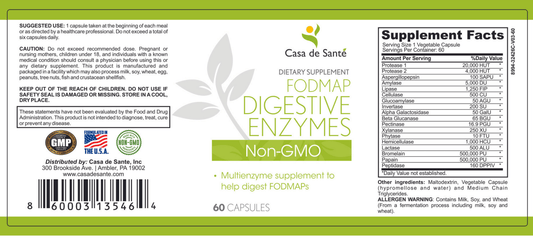

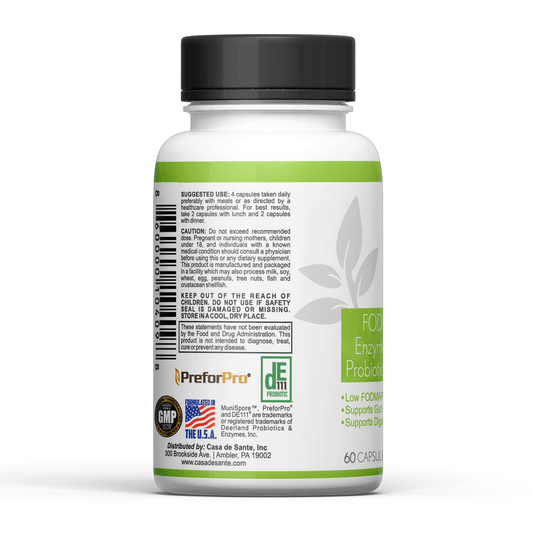

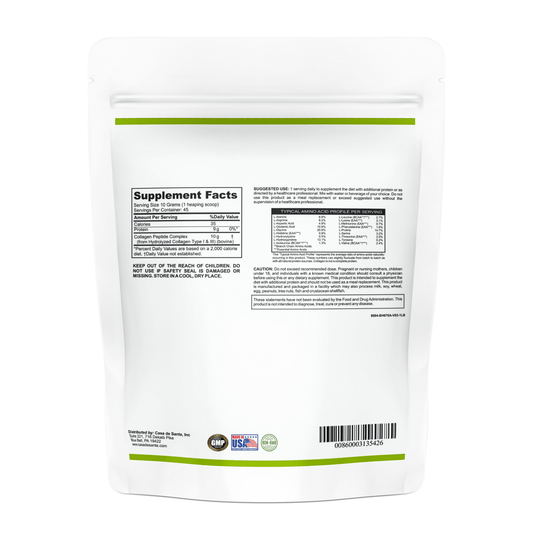

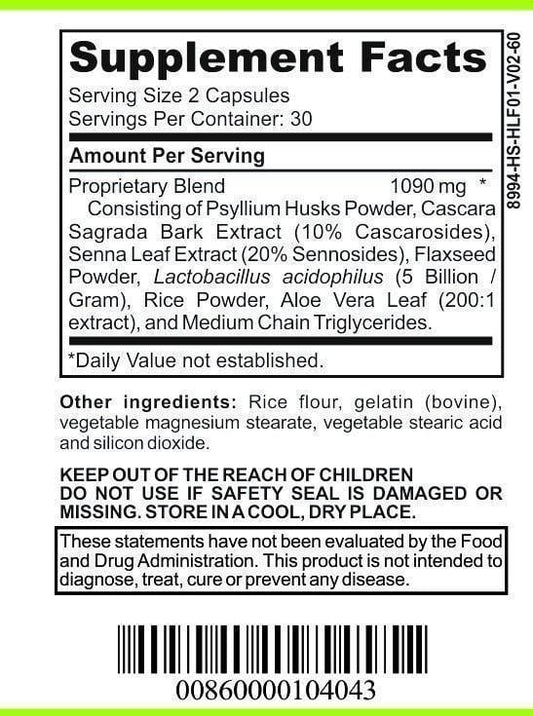

In food processing, fructan hydrolases play multiple roles. They're used to produce high-fructose syrups from inulin-rich plant sources, offering an alternative to corn-based sweeteners. These enzymes also help improve the functional properties of certain food ingredients by modifying their fructan content. For instance, treating wheat flour with fructan hydrolase can reduce the content of FODMAPs (Fermentable Oligosaccharides, Disaccharides, Monosaccharides, and Polyols), making products more suitable for individuals with irritable bowel syndrome.

The beverage industry employs fructan hydrolases in processes like fruit juice clarification and alcohol production. In brewing, these enzymes can break down fructans from barley or wheat that might otherwise cause haziness in the final product. Some specialty beers even leverage fructan hydrolases to create unique flavor profiles by releasing fructose that contributes sweetness and serves as a substrate for fermentation.

Biofuel Production

As the world seeks alternatives to fossil fuels, fructan hydrolases have emerged as valuable tools in biofuel production. Inulin-rich plants like Jerusalem artichoke can be processed using these enzymes to release fermentable sugars for bioethanol production. The process is more efficient than starch-based ethanol production because fructans require less pretreatment before enzymatic hydrolysis.

Recent advancements in enzyme engineering have yielded fructan hydrolase variants with enhanced stability and activity under the conditions typical of industrial biofuel production. These improvements have made fructan-based biofuels more economically competitive, potentially expanding their role in the renewable energy landscape.

Pharmaceutical and Medical Applications

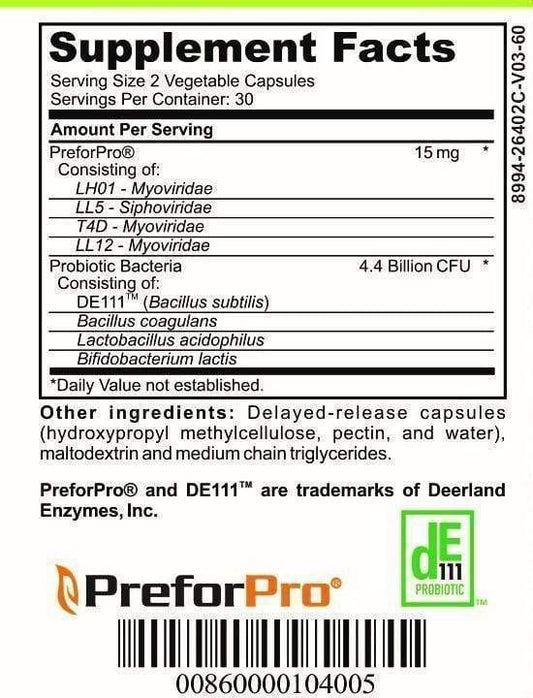

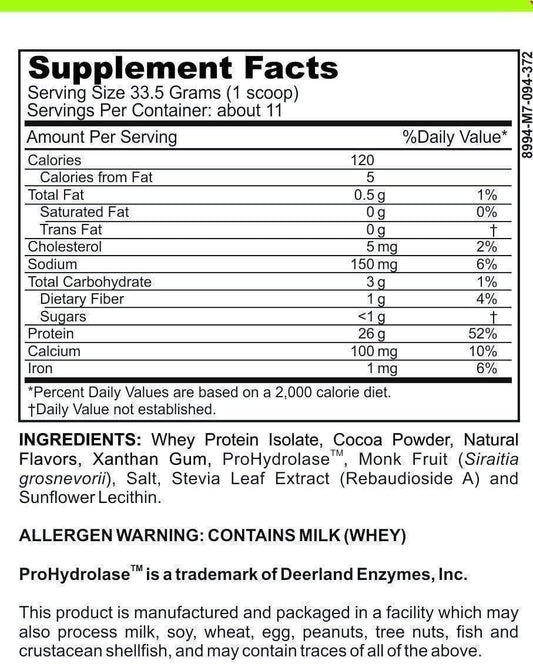

The pharmaceutical sector has found valuable applications for fructan hydrolases in drug development and diagnostics. These enzymes are used to produce high-purity fructose and fructooligosaccharides (FOS) that serve as excipients in pharmaceutical formulations or as prebiotic ingredients in functional foods and supplements. The prebiotic effects of FOS, which selectively stimulate beneficial gut bacteria, have been linked to improved digestive health and enhanced immune function.

In medical diagnostics, fructan hydrolases are employed in assays to measure fructan content in biological samples. This capability is particularly relevant for research on fructan metabolism disorders and for monitoring patients with fructan sensitivity conditions like FODMAP intolerance. Some innovative therapeutic approaches are also exploring the potential of engineered fructan hydrolases as oral supplements to aid digestion in individuals with fructan malabsorption issues.

Future Perspectives and Challenges

The field of fructan hydrolase research continues to evolve, with new discoveries expanding our understanding of these versatile enzymes. Advances in protein engineering and directed evolution techniques are yielding enzyme variants with enhanced properties, such as improved thermostability, altered substrate specificity, or optimized activity under specific pH conditions. These engineered enzymes could open new applications or improve the efficiency of existing processes.

Synthetic biology approaches are also being explored to create novel fructan hydrolases with unprecedented capabilities. By combining protein domains from different enzymes or introducing non-natural amino acids, researchers aim to develop biocatalysts that can process challenging substrates or perform reactions not found in nature. Such innovations could revolutionize how we utilize fructan resources.

Emerging Applications

Several emerging applications for fructan hydrolases show promise for addressing contemporary challenges. In agriculture, these enzymes are being investigated as components of biostimulants that can enhance crop resilience to environmental stresses. By modulating fructan metabolism in plants or soil microbiomes, these enzyme-based products could help maintain agricultural productivity in the face of climate change.

In the realm of functional materials, fructan hydrolases are enabling the production of fructose-based polymers with unique properties. These biopolymers offer biodegradable alternatives to petroleum-derived plastics, potentially contributing to solutions for plastic pollution. The precise control offered by enzymatic processing allows for tailored material properties suitable for specific applications, from packaging to medical devices.

Challenges and Limitations

Despite their potential, several challenges limit the broader adoption of fructan hydrolase technologies. Production costs remain a significant barrier, particularly for applications in price-sensitive markets. Improving enzyme expression systems and developing more efficient recovery processes could help address this limitation. Additionally, some fructan hydrolases exhibit suboptimal stability under industrial conditions, necessitating careful process design or enzyme immobilization strategies.

Regulatory considerations also present challenges, especially for novel applications in food or medical contexts. Ensuring the safety and efficacy of enzyme preparations requires rigorous testing and documentation. However, as the body of research on fructan hydrolases grows and regulatory frameworks evolve to accommodate biocatalytic processes, these hurdles are gradually being overcome, paving the way for wider implementation of these remarkable enzymes across diverse sectors.