Why do you choose not to use fillers in your products when ...

Why do you choose not to use fillers in your products when ...

As consumer awareness grows and more people seek products that align with their values and health concerns, the use of fillers in products has become a topic of discussion. Businesses are faced with the question: Why choose not to use fillers in your products when there are potential advantages to doing so? Understanding fillers, their common uses, and the impact of not using them can provide valuable insights into this decision-making process.

Understanding Fillers: What They Are and Their Common Uses

When it comes to product manufacturing, fillers are an important component that often goes unnoticed. These non-active ingredients are added to formulations for various reasons, such as increasing bulk, improving stability, enhancing texture, or maintaining a desired consistency. While they may not be the star of the show, fillers play a crucial role in the overall quality and performance of a product.

Definition of Fillers

Let's dive a little deeper into the definition of fillers. In the context of product manufacturing, fillers are substances that are added to a formulation to serve specific purposes. These substances are often inexpensive, readily available, and widely used across various industries. They are not the main active ingredients but rather support the product's functionality and characteristics.

Common Types of Fillers in Products

There is an extensive range of fillers utilized in different products, catering to the unique needs of each industry. Some of the commonly used fillers include powdered clays, cellulose derivatives, starches, or synthetic compounds like silicones. Each filler type brings its own set of benefits and properties, allowing manufacturers to tailor their products to specific requirements.

For example, powdered clays are often used as fillers in cosmetic products such as foundations or powders. These clays not only add bulk to the formulation but also provide a smooth texture and help control oiliness on the skin. On the other hand, cellulose derivatives, such as methylcellulose or hydroxypropyl cellulose, are frequently used in pharmaceutical tablets, acting as disintegrants to aid in the breakdown and dissolution of the tablet.

The Role of Fillers in Product Manufacturing

Now, let's explore the role of fillers in product manufacturing. Fillers are not just added for the sake of it; they serve a specific purpose in the formulation. By incorporating fillers, manufacturers can achieve desired product properties while also optimizing cost-effectiveness.

One of the primary benefits of using fillers is their ability to contribute to the texture of the product. Whether it's a creamy lotion or a powdery foundation, fillers help create the desired consistency that consumers expect. They can also enhance the viscosity of a product, making it easier to apply or spread evenly on the skin.

In addition to texture and viscosity, fillers also play a crucial role in maintaining the stability of a product. They can prevent ingredients from separating or settling, ensuring a homogeneous formulation throughout the product's shelf life. This stability not only improves the overall performance of the product but also extends its longevity, allowing consumers to enjoy it for a longer period.

However, it's important to note that the choice of fillers should be made carefully, considering their impact on health and consumer preferences. Some fillers may have potential allergenic properties or may not align with certain ethical or environmental standards. Manufacturers need to strike a balance between functionality, cost-effectiveness, and consumer safety when selecting fillers for their products.

So, the next time you come across a product, take a moment to appreciate the role of fillers in its formulation. These seemingly insignificant ingredients are the unsung heroes that contribute to its texture, stability, and overall performance. Understanding fillers and their common uses can give you a deeper appreciation for the complexity and thoughtfulness behind the products we use every day.

The Reasons for Choosing Not to Use Fillers

Health Concerns Associated with Fillers

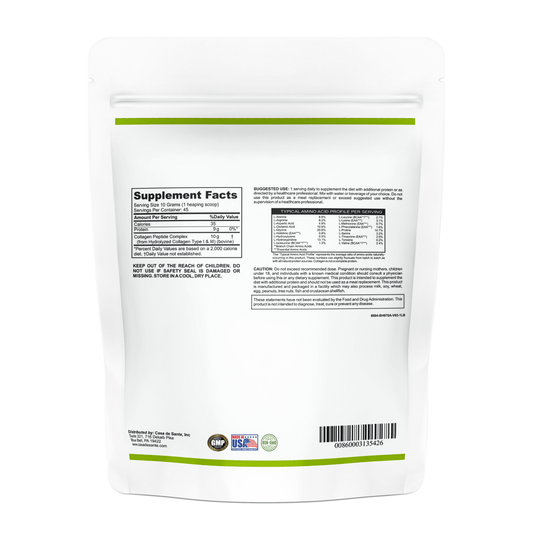

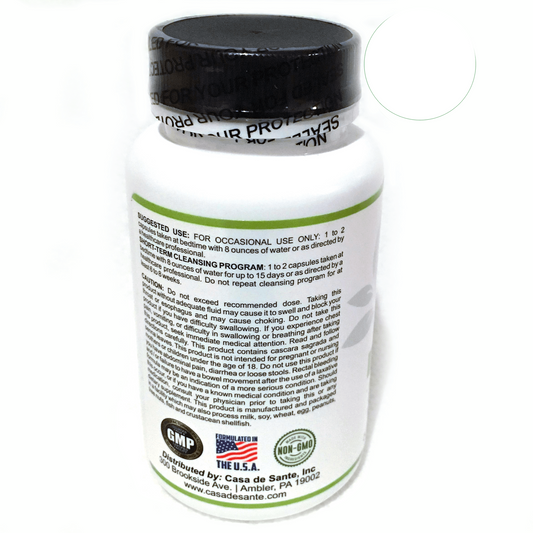

One of the primary reasons businesses choose not to use fillers in their products is the potential health concerns associated with certain filler ingredients. While many fillers are considered safe for use, some individuals may have allergies or sensitivities to specific substances. For example, some fillers may contain common allergens such as soy, gluten, or dairy, which can trigger adverse reactions in susceptible individuals. Moreover, certain fillers have been linked to potential side effects or long-term health risks, making their exclusion a priority for health-conscious consumers.

Furthermore, it is essential to consider the impact of fillers on the body's absorption and metabolism. Some fillers may interfere with nutrient absorption or disrupt the body's natural processes, potentially leading to imbalances or complications. By avoiding fillers, businesses can prioritize the well-being of their customers and ensure that their products do not pose any unnecessary risks to their health.

Quality Control and Product Integrity

Another compelling reason to avoid fillers is to maintain stringent quality control and enhance product integrity. Fillers can dilute the concentration of active ingredients, making it difficult to ensure consistent product performance. This dilution effect may compromise the effectiveness of the product and hinder its ability to deliver the desired results.

By omitting fillers, businesses can focus on delivering products with higher concentrations of active ingredients, resulting in a more potent and reliable end product. This approach allows companies to maintain better control over the formulation process and ensure that each product meets the highest quality standards. Customers can trust that the products they purchase are free from unnecessary additives and will deliver the intended benefits consistently.

Consumer Demand for Natural and Pure Products

Consumer demand for natural and pure products continues to rise, with an emphasis on simplicity and transparency in ingredient labels. Many individuals are becoming more conscious of what they put on their skin or consume, seeking products that align with their values and preferences.

Removing fillers from formulations aligns with this demand, allowing businesses to communicate a commitment to providing clean, minimally processed products. Customers appreciate knowing exactly what they are applying to their bodies or ingesting, and the absence of fillers contributes to a sense of trust and transparency. By addressing the concerns of ingredient-conscious consumers, companies can establish trust and build a loyal consumer base that values their commitment to natural and pure products.

Moreover, the absence of fillers in products can also have environmental benefits. Many fillers are derived from non-renewable resources or require extensive processing, contributing to environmental degradation. By opting for filler-free formulations, businesses can reduce their ecological footprint and contribute to a more sustainable future.

The Impact of Not Using Fillers on Product Development

When it comes to product development, the decision to not use fillers can have a significant impact. While fillers are commonly used to enhance texture, stability, and consistency, manufacturing products without them presents its own set of challenges.

Challenges in Manufacturing Without Fillers

Formulas that do not include fillers require meticulous formulation optimization. Without the contributions of fillers, developers must carefully adjust the ingredients to achieve the desired product properties. This process can be time-consuming and may require extensive testing to ensure that the final product meets quality standards.

In addition to formulation challenges, the absence of fillers may also necessitate modifications to the manufacturing processes. These modifications could include changes to equipment or production techniques, which can lead to increased production costs or longer development timelines. Manufacturers must carefully evaluate these factors to determine if the benefits of filler-free products outweigh the potential drawbacks.

Innovations in Filler-Free Product Development

Despite the challenges, manufacturers and industry leaders have embraced the opportunity to develop innovative products without fillers. Advancements in ingredient technology and formulation expertise have allowed for the creation of effective alternatives and novel approaches to achieving desired product properties.

For example, researchers have discovered natural ingredients that can mimic the texture and stability provided by fillers. These ingredients, such as plant-based extracts or specialized proteins, offer a more sustainable and consumer-friendly alternative to traditional fillers.

Furthermore, the development of filler-free products not only improves the consumer experience but also drives sustainability and competitiveness in the market. By eliminating unnecessary additives, manufacturers can reduce their environmental footprint and appeal to consumers who prioritize clean and natural products.

The Cost Implications of Not Using Fillers

One significant consideration when choosing not to use fillers is the potential cost implications. Fillers are often used to reduce manufacturing expenses, as they can bulk up the product without adding significant cost. However, the absence of fillers may lead to higher production costs due to the need for alternative ingredients or formulation modifications.

Despite the potential increase in production costs, many companies can justify higher price points for filler-free products. By positioning these products as premium offerings, companies can tap into the growing demand for clean and natural products. Consumers are often willing to pay a premium for products that align with their values and provide superior quality.

In conclusion, the impact of not using fillers on product development is multifaceted. While it presents challenges in formulation and manufacturing, it also opens doors for innovation and sustainability. By carefully considering the cost implications and leveraging consumer demand, companies can navigate the complexities of filler-free product development and create unique offerings in the market.

Case Studies of Successful Filler-Free Products

Filler-Free in the Food Industry

In the food industry, several brands have found success by utilizing natural, unadulterated ingredients and avoiding fillers. By prioritizing quality, these brands have created unique selling propositions and captured the attention of health-conscious consumers seeking minimally processed alternatives. The focus on ingredient integrity and a commitment to transparent labeling have become key differentiators, enabling these products to thrive.

Beauty Products Without Fillers

In the beauty industry, the demand for cleaner, more natural alternatives has prompted many companies to develop filler-free products. By harnessing the power of botanical extracts and other active ingredients, these brands cater to consumers who prioritize skincare and cosmetics that offer real benefits without unnecessary additives. As a result, they have gained recognition for their commitment to ingredient purity and product efficacy.

Eco-friendly Household Products Without Fillers

Filler-free household products have also gained traction among environmentally conscious consumers. By eliminating fillers, these brands reduce their ecological impact and provide customers with effective, clean alternatives. By focusing on ingredient integrity and utilizing eco-friendly packaging, these products contribute to sustainable living and attract environmentally conscious consumers.

In conclusion, the decision to omit fillers from products is driven by various factors, including health concerns, quality control, and consumer demand for natural and pure alternatives. While manufacturing without fillers presents challenges, advancements in formulation technology and innovative approaches enable businesses to create effective and competitive filler-free products. Case studies across industries demonstrate the success of these endeavors, catering to ingredient-conscious consumers and driving positive change in the market. Ultimately, the choice to forego fillers is a strategic one, allowing businesses to align with consumer values and contribute to a healthier, more transparent marketplace.