Polyols

Polyols, also known as sugar alcohols, are a versatile group of compounds that have gained significant attention in various industries due to their unique properties. This article provides an in-depth exploration of polyols, including their definition, types, chemical structure and properties, production and manufacturing processes, as well as their wide-ranging applications in the food, pharmaceutical, and cosmetic industries.

Introduction to Polyols

Polyols are a class of organic compounds that are characterized by the presence of multiple hydroxyl (-OH) groups. These compounds are derived from various sources and are widely used in different industries due to their desirable attributes, such as low calorie content, reduced glycemic index, low cariogenicity, and their ability to act as humectants, bulking agents, and sweeteners.

Definition and Basic Understanding

Polyols, in a chemical sense, are alcohols that contain more than one hydroxyl group. These non-sugar carbohydrates can be naturally occurring or produced synthetically. They encompass a diverse range of compounds, including sugar alcohols and polyether or polyester polyols.

One of the most commonly known polyols is sorbitol. Sorbitol is a sugar alcohol that occurs naturally in various fruits and berries. It is widely used as a sweetener in food and beverages, especially in sugar-free or low-calorie products. Sorbitol has approximately 60% of the sweetness of sucrose and is often used as a sugar substitute for individuals who need to manage their blood sugar levels.

Another type of polyol is xylitol, which is found in many fruits and vegetables, as well as in birch bark. Xylitol has gained popularity as a sugar substitute due to its low glycemic index and its ability to prevent tooth decay. In fact, xylitol is often used in chewing gums and oral care products because it can inhibit the growth of bacteria that cause dental cavities.

Historical Background of Polyols

The use of polyols dates back centuries, with evidence of their utilization in ancient civilizations like the Egyptians and Greeks. In ancient Egypt, honey was used as a sweetener and preservative, and it contains various polyols such as sorbitol and mannitol. The Greeks, on the other hand, used honey and figs to produce a sweet syrup called "defrutum," which was rich in polyols.

However, the commercial production and application of polyols gained prominence in the 20th century with advancements in chemical synthesis and refining processes. The development of new technologies allowed for the production of polyols on a larger scale, making them more accessible and affordable for various industries.

Today, polyols are an integral part of numerous industries. In the food and beverage industry, they are used as sweeteners, bulking agents, and humectants. In the pharmaceutical industry, polyols are utilized in the production of medicines, syrups, and oral care products. In the cosmetics industry, they can be found in moisturizers, lotions, and other skincare products due to their humectant properties.

Moreover, polyols have applications in the manufacturing of polyurethane foams, which are widely used in the construction, automotive, and furniture industries. These foams provide insulation, cushioning, and structural support due to their unique properties. Polyols are combined with isocyanates to form polyurethane, creating a versatile material that can be molded into various shapes and used in different applications.

In conclusion, polyols are a diverse class of compounds that have been used for centuries and continue to play a crucial role in various industries. Their unique properties, such as low calorie content, reduced glycemic index, and ability to act as sweeteners, humectants, and bulking agents, make them highly valuable in food and beverage, pharmaceutical, cosmetic, and manufacturing sectors.

Types of Polyols

Polyols are a diverse group of compounds that can be classified into different categories based on their chemical structures and sources. Understanding the different types of polyols is crucial in various industries, such as food and beverage, construction, and manufacturing. Let's explore the most common types of polyols in more detail.

Sugar Alcohols

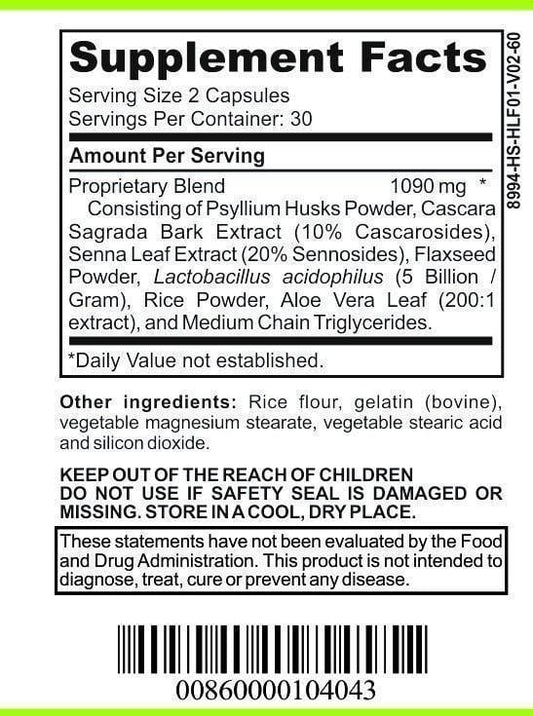

Sugar alcohols are a type of naturally occurring polyols that are derived from various plant and fruit sources. Examples of sugar alcohols include sorbitol, xylitol, and maltitol. These compounds possess a sweet taste, making them popular as sugar substitutes in numerous food and beverage products. Sugar alcohols are often used in sugar-free chewing gums, candies, and baked goods. They provide sweetness without causing a significant increase in blood sugar levels, making them suitable for individuals with diabetes or those following a low-carbohydrate diet.

In addition to their sweetening properties, sugar alcohols also have other benefits. They have a lower caloric content compared to regular sugar, making them a favorable choice for people looking to reduce their calorie intake. Furthermore, sugar alcohols are not fermented by oral bacteria, reducing the risk of tooth decay. Some studies suggest that sugar alcohols may also have prebiotic effects, promoting the growth of beneficial gut bacteria.

Polyether Polyols

Polyether polyols are a type of synthetic compounds that are widely used in various industries. They are produced through the reaction of epoxides with multifunctional initiators, such as glycerol or propylene oxide. This reaction results in a chain of repeating units, giving polyether polyols their unique properties.

One of the key advantages of polyether polyols is their high reactivity. This allows manufacturers to tailor the properties of the polyols to meet specific requirements. For example, by adjusting the molecular weight and functionality of the polyether polyols, they can be used to produce flexible foams with varying levels of softness and resilience. These foams are commonly used in mattresses, cushions, and upholstery.

Polyether polyols are also used in the formulation of coatings, adhesives, and sealants. Their excellent compatibility with various additives and solvents makes them a versatile choice in these applications. Additionally, polyether polyols offer good resistance to moisture, chemicals, and UV radiation, ensuring the durability and longevity of the products they are used in.

Polyester Polyols

Polyester polyols are another important category of polyols that find applications in a wide range of industries. They are formed by the reaction of diacids or their ester precursors with diols. This reaction results in the formation of a polyester backbone, which contributes to the unique properties of these polyols.

One of the key advantages of polyester polyols is their exceptional mechanical properties. They offer high strength, toughness, and abrasion resistance, making them ideal for applications that require durability and long-term performance. Rigid foams, elastomers, and coatings often utilize polyester polyols to achieve these desired properties.

Furthermore, polyester polyols exhibit excellent chemical resistance, making them suitable for use in environments where exposure to harsh chemicals is expected. Their thermal stability also allows them to withstand high temperatures without significant degradation, making them a reliable choice for applications in extreme conditions.

In conclusion, polyols are a diverse group of compounds that offer unique properties and benefits. Sugar alcohols provide sweetness without the negative effects of regular sugar, making them suitable for individuals with specific dietary needs. Polyether polyols offer versatility and reactivity, allowing manufacturers to customize their products to meet specific requirements. Polyester polyols, on the other hand, provide exceptional mechanical and chemical properties, making them ideal for applications that demand durability and resistance. Understanding the different types of polyols enables industries to make informed decisions when selecting the appropriate polyol for their specific needs.

Chemical Structure and Properties of Polyols

Polyols, also known as polyhydric alcohols, are a class of compounds that play a crucial role in various industries. They are characterized by their unique molecular structures, which significantly influence their properties and applications.

Molecular Structure

The molecular structure of polyols is diverse and complex, with variations in the arrangement of atoms and functional groups. This structural diversity gives rise to a wide range of properties and behaviors exhibited by polyols.

One important aspect of the molecular structure is the presence of hydroxyl groups (-OH) attached to carbon atoms. The number and position of these hydroxyl groups determine the hydrophilic or hydrophobic nature of polyols. Hydrophilic polyols have a high affinity for water, while hydrophobic polyols repel water.

In addition to hydroxyl groups, the degree of branching, cross-linking, and functionality also contribute to the molecular structure of polyols. Branching refers to the presence of side chains or branches in the polyol molecule, which can affect its solubility and reactivity. Cross-linking occurs when the polyol chains are connected by chemical bonds, resulting in a three-dimensional network. The functionality of a polyol refers to the number of hydroxyl groups present in its structure, which influences its reactivity and ability to form bonds with other substances.

These factors collectively determine the physical and chemical properties of polyols, making them versatile compounds with a wide range of applications.

Physical and Chemical Properties

Polyols exhibit diverse physical and chemical properties, which make them suitable for various industrial applications.

One important property of polyols is viscosity, which refers to their resistance to flow. Viscosity can vary widely depending on the molecular weight and structure of the polyol. High molecular weight polyols tend to have higher viscosity, while low molecular weight polyols have lower viscosity. This property is crucial in applications such as adhesives, where the viscosity of the polyol determines its ease of application and bonding strength.

Another important property is the melting point of polyols. The melting point is the temperature at which a solid polyol changes to a liquid state. Polyols with higher molecular weight and more complex structures tend to have higher melting points. This property is significant in applications such as coatings and plastics, where the melting point of the polyol affects the processing temperature and the final properties of the material.

Solubility is another important property of polyols. The ability of a polyol to dissolve in a particular solvent depends on its molecular structure and the nature of the solvent. Hydrophilic polyols are soluble in water, while hydrophobic polyols are soluble in nonpolar solvents. This property is crucial in applications such as pharmaceutical formulations and personal care products, where the solubility of the polyol affects its bioavailability and stability.

Reactivity is a key property that determines the ability of polyols to undergo chemical reactions. The presence of hydroxyl groups in the polyol structure makes them highly reactive, allowing them to form bonds with other substances. This property is exploited in applications such as polyurethane foams, where the reactivity of the polyol is crucial for the formation of the foam structure.

Compatibility with other substances is also an important property of polyols. The ability of a polyol to mix or blend with other materials without phase separation or loss of properties is critical in various applications. For example, in the food industry, polyols are used as sugar substitutes due to their compatibility with other ingredients and their ability to provide sweetness without contributing to calorie content.

Overall, the physical and chemical properties of polyols play a vital role in determining their suitability for specific applications. Their diverse range of properties, combined with their unique molecular structures, make them valuable compounds in industries such as food and beverage, pharmaceuticals, adhesives, and plastics.

Production and Manufacturing of Polyols

The production and manufacturing processes of polyols involve a series of steps to obtain the desired chemical composition and physical properties.

Raw Materials and Preparation

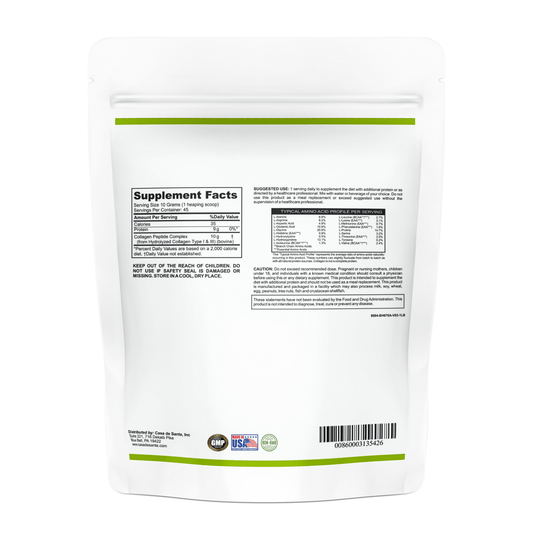

Polyols can be derived from various starting materials, such as renewable resources like corn, wheat, or soy, as well as petroleum-based feedstocks. These raw materials undergo specific preparation methods, including extraction, purification, and chemical modifications, to obtain the desired polyol composition.

Manufacturing Process

The manufacturing process of polyols typically involves chemical reactions, such as esterification or hydrogenation, to produce the desired polyol from the starting materials. The processes may vary depending on the type of polyol being produced and the intended application.

Applications of Polyols

The versatile properties of polyols have resulted in their widespread use across various industries, ranging from food and pharmaceuticals to cosmetics.

Food Industry

Polyols are extensively utilized as food additives, providing sweetness, texture, and stability to a wide range of products. They are commonly found in sugar-free candies, chewing gums, baked goods, and beverages. Moreover, polyols are well-recognized for their lower caloric content compared to traditional sugars, making them suitable for diabetic or low-carbohydrate diets.

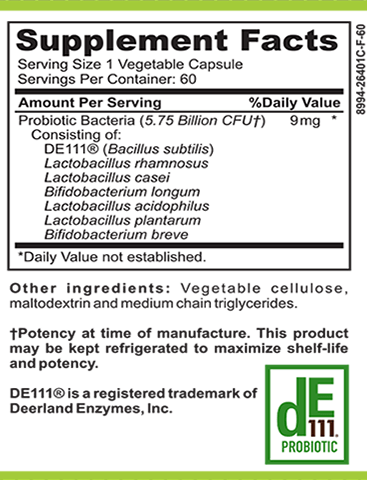

Pharmaceutical Industry

Polyols are essential components in pharmaceutical formulations, playing crucial roles in drug delivery systems, excipients, and dosage forms. Their ability to improve the solubility, stability,